H Y D R A U L I C

S Y S T E M

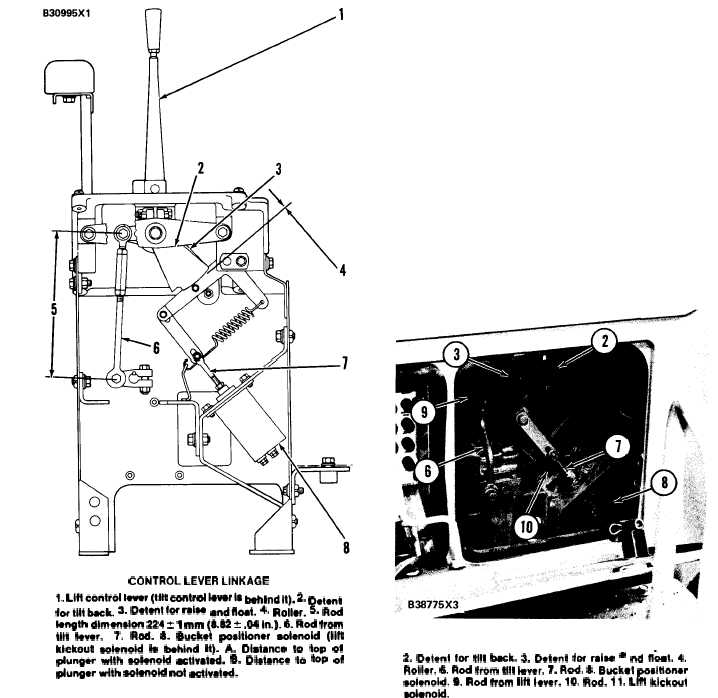

CONTROL LEVER LINKAGE ADJUSTMENT

CONTROL LEVER LINKAGE

l. Llftcontrol lever (tilt COntikwrls Mlndlt). 2. D@ent

lortlltbeck. 3. Dotentbrrcieew Idffat. 4. Roller. S. Rod

length dimension 224 t 1 mm (8.32? .04 in.). 6. Rod from

tilt fever.

7. Rod. 8. Bucket positioner eolenoid (lift

kickout eolonoid b behind it). A. Distcnce to top ot

plunger with eolenotd ectivated. B. Diet-e to toP of

pfunger wfth colenokf not ectivated.

TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

Control lever linkage adjustment must be made

with the lift arms at maximum height and the buck-

et in the tilt back position. This is done so that both

the lift and tilt (bucket positioner) kickout solenoids

can be easily activated.

1.

2.

3.

Make sure that the lift kickout and bucket

positioner are adjusted correctly. The magnet for

the lift kickout must be in the correct position.

The switch for the bucket positioner must be in

the correct position. See their respective AD-

JUSTMENT PROCEDURES.

Open the cover on the right side of the cab.

Rods (6) and (9) must have length dimension (5)

of 224 ± 1 mm (8.82 ± .04 in.) between the

centers of the bolts through the ends. Loosen

a locknut against an end and remove the bolt

through the end of the rod. Turn the end either

clockwise or counterclockwise to change the

length of the rod.

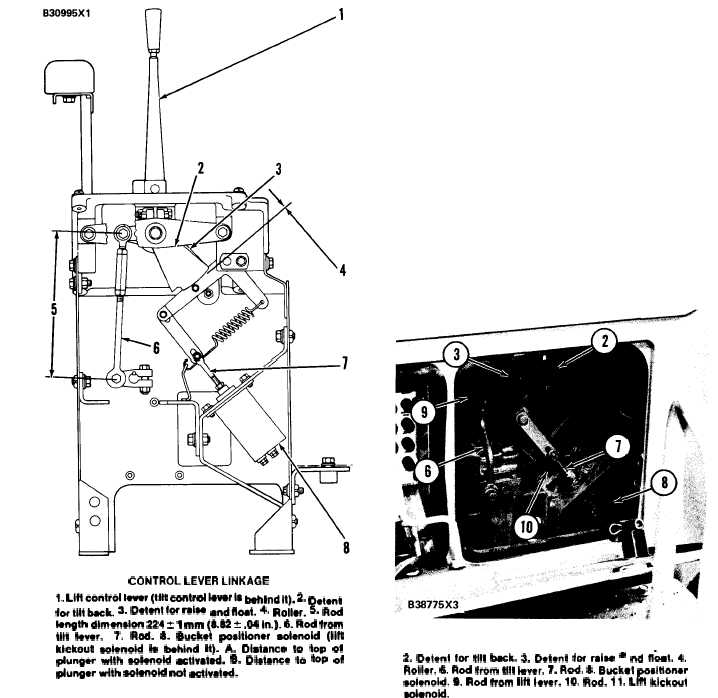

R I G H T S I D E O F C AB

2. Detent for tilt beck. 3. Detent for rcise l nd ft-mt. 4.

Roller. 6. Rod from tilt lever. 7. Rod. 8. Bucket positioner

soienoid. 9. Rod from lift iever. 10. Rod. 11. Lfff kickout

eoienoid.

4-79