TM 5-3805-258-24-1

9 5 0 B O P E R A T O R ’ S

S T A T I O N

E L E C T R I C A L T R O U B L E S H O O T I N G

Bucket Positioner

The bucket positioner uses a 9G116 Switch Assembly that is activated by a

magnet that moves in and out with the tilt cylinder rod. The bucket positioner

system is different than the lift kickout in that it “latches up” (the kickout keeps

activated).

The 950B uses pilot valve operated hydraulic controls that need only a small

force to operate the implement. The tilt back detent needs greater force to move

the lever out of the TILT BACK position. In many applications the lever must

be moved from HOLD to and from TILT BACK, several times when the bucket

is to be filled. The large force necessary to move the lever from the detent would

make the machine much harder to use. For this reason, when the kickout is first

activated with the bucket level, the kickout “latches up” (keeps activated) while

the bucket is tilted back farther during the procedure of getting a load. The

detent is prevented from operation until the bucket is dumped (tilted forward)

past the level position. Then the circuit unlatches (disconnects) and the detent is

again ready to operate.

The “latch up” is done completely by the 9G116 Switch Assembly. When the

bucket is tilted back, the magnet moves from position A toward position B. The

magnet has no effect at position B, but at position C it causes the switch to

electronically connect Pin 2 to Pin 3 of the harness plug. This activates the

9G9891 Bucket Positioner Solenoid.

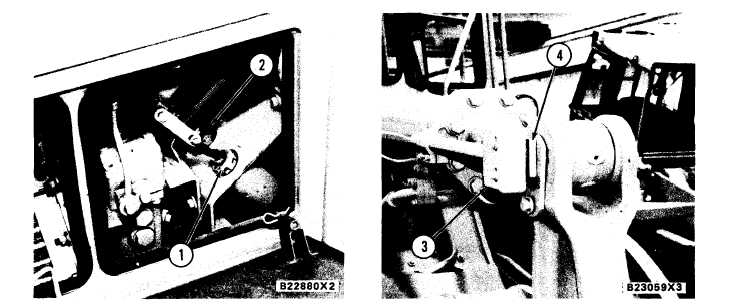

L I F T K I C K O U T A N D B U C K E T P O S I T I O N E R S O L E N O I DS

1. Lift kickout solenoid. 2. Bucket position solenoid.

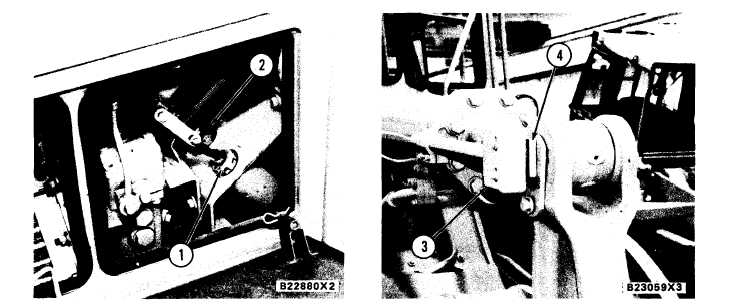

B U C K E T P O S I T I O N E R S W I T C H A N D M A G N ET

3. Bucket positioner switch. 4. Bucket positioner magnet.

4-131