TM 5-3805-258-24-2

ENGINE

DISASSEMBLY AND ASSEMBLY

CRANKSHAFT PULLEY

REMOVE CRANKSHAFT PULLEY

1205-11

Tools Needed

A

8B7559

Adapter

2

8B7561

Step Plate

1

8B7550

Leg

2

8H684

Ratchet Box Wrench

1

8B7548

Puller Assembly

1

1.

2.

3.

start by:

a) remove radiator and guard

b) remove fan

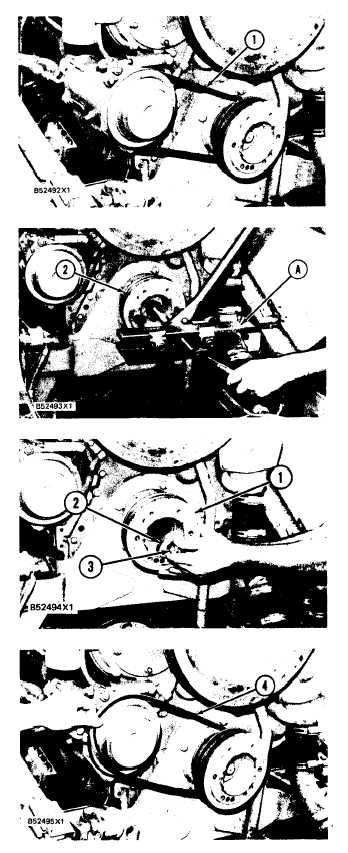

Loosen the nuts and bolts from the air condi-

tioner compressor and remove vee belt (1) (if so

equipped).

Loosen the bolt in the end of crankshaft pulley

(2) until there is approximately 9.5 mm (3/8”)

between the retainer and crankshaft pulley. In-

stall tooling (A) and loosen crankshaft pulley

(2) from the crankshaft.

Remove tooling (A), the bolt, washer and

crankshaft pulley (2) from the crankshaft.

INSTALL CRANKSHAFT PULLEY

1205-12

Tools Needed

A

Borroughs Tool Company Part No.

BT-33-95

1

1.

2.

3.

4.

5.

6.

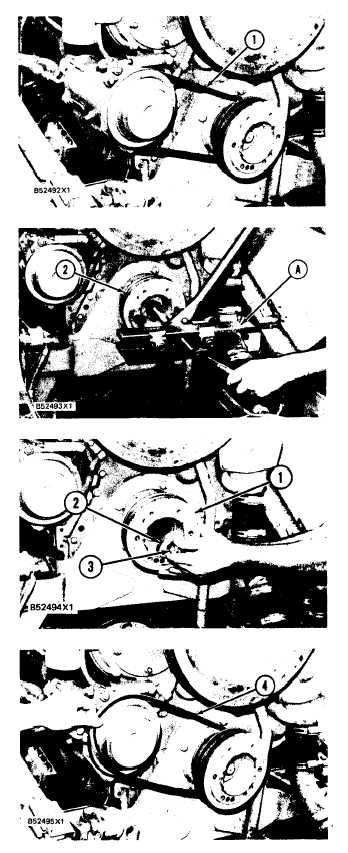

Put crankshaft pulley (1) in position on the

crankshaft.

Install washer (2) so the maximum flat area is

next to the crankshaft pulley and bolt (3) as

shown.

Install two ½”-l3 NC bolts 2 in. long in the

pulley. Put a pry bar between the bolts and

against the frame so the crankshaft will not

turn while bolt (2) is tightened to the correct

torque.

Tighten bolt (2) to a torque of 312 ± 27 N·m

(230 ± 20 lb. ft.). Hit the bolt with a hammer.

Tighten the bolt again to a torque of 312 ± 27

N·m (231 ± 20 lb.ft.).

Install vee belt (4) on the air conditioner

compressor and the crankshaft pulley (if so

equipped).

Use tool (A) to measure the belt tension. Ad-

just the belt tension until the gauge reading for

a new belt is 534 ± 22 N (120 ± 5 lb.). Adjust

the belt tension until the gauge reading for a

used belt is 400 ± 44 N (90 ± 10 lb.). A used

belt is one which has more than 30 minutes of

operation at rated engine speed. When the belt

tension is correct, tighten all the bolts and nuts

in the mounting bracket.

5-58