ENGINE

TM 5-3805-258-24-2

DISASSEMBLY AND ASSEMBLY

CRANKSHAFT AND GEAR

REMOVE CRANKSHAFT

AND GEAR

1202 & 1204-11

Tools Needed

A

8B7548

Puller Assembly

1

8H684

Ratchet Box Wrench

1

8B7560

Step Plate

1

8B7551

Bearing Puller Attachment

1

1.

2.

3.

4.

5.

start by:

a) remove hydraulic pump gear train

b) remove timing gear cover

c) remove pistons

Install a 3/4" - 16 NC bolt in the gear end of the

crankshaft. Install two 5/8”- 18 NF bolts in the

flywheel end of the crankshaft. Fasten a hoist

to the crankshaft.

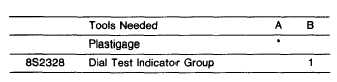

Remove main bearing caps (1).

Remove the crankshaft from the cylinder

block. Weight of the crankshaft is approxima-

tely 65 kg (145 lb.).

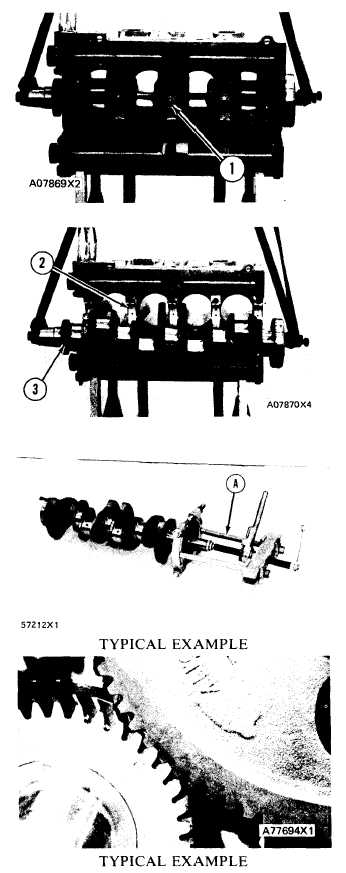

Remove main bearings (2) from the block and

from the caps. Remove the thrust bearings.

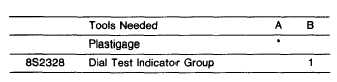

Use tooling (A) to remove gear (3) from the

crankshaft.

INSTALL CRANKSHAFT

AND GEAR

1201 & 1204-12

1.

2.

3.

4.

Heat the crankshaft gear to a maximum tem-

perature of 315°C(600°F). Install the gear on

the crankshaft with the “C” mark on the gear

toward the pulley end of the crankshaft.

Clean the surfaces on the cylinder block for the

main bearings. Install the upper halves of the

main bearings in the block. Put clean engine oil

on the bearings.

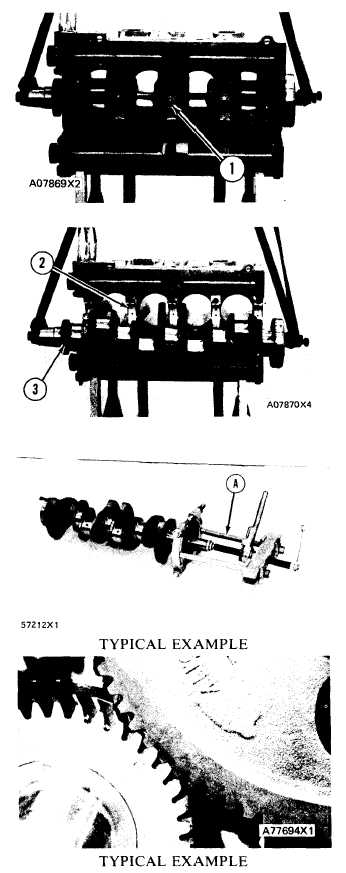

Turn the camshaft so the “C” mark on the

camshaft gear will be toward the “C” mark on

the crankshaft gear when the crankshaft is in-

stalled. Put the crankshaft in position in the

cylinder block with a hoist. Make sure the tim-

ing marks on the camshaft gear and crankshaft

gear are in alignment as shown.

Clean the Nos. 1 and 5 main bearing caps.

Install new bearings in the caps. Put clean en-

gine oil on the bearings. Temporarily install the

caps to hold the crankshaft in place.

5-145