ENGINE

CYLINDER

c)

d)

e)

Check to be sure the distance from the bot-

tom edge of the crossbar to the top of the

cylinder block is the same on both sides of

the liner.

Check the cylinder liner projection with

tool group (C) at four locations around the

liner.

Liner projection must be 0.033 to 0.175 mm

(.0013 to .0069 in.). Measurements on the

same liner must not be different by more

than 0.05 mm (.002 in.). Average measure-

ments between liners next to each other

must not be different by more than 0.05

mm (.002 in.).

NOTE: If the liner is turned in the bore, it can make

a difference in the liner projection.

4. If the liner projection is not 0.033 to 0.175 mm

(.0013 to .0069 in.), check the thickness of the

following parts: spacer plate, spacer plate gas-

ket and cylinder liner flange. The thickness of

the spacer plate must be 9.970 ± 0.025 mm

(.3925 ± .0010 in.). The thickness of the

spacer plate gasket must be 0.208 ± 0.025 mm

(.0082 ± .0010 in.). The thickness of the cylin-

der liner flange must be 10.282 ± 0.020 mm

(.4048 ± .0008 in.).

NOTE: If the liner projection changes from point to

point around the liner, turn the liner to a new position

in the bore. If the liner projection is still not to

specifications, move the liner to a different bore.

5. When the cylinder projection is correct, put a

mark on the liner and block so the liner can be

installed in the same position from which it was

removed.

NOTE: Cylinder liner projection can be adjusted by

the removal of material from (machining) the con-

tact face of the cylinder block with the use of the

8S3140 Cylinder Block Counterboring Tool Ar-

rangement. Machine to a minimum depth of 0.76

mm (.030 in.) and to a maximum depth of 1.14 mm

(.045 in.). The instructions for the use of the tool

group are in

Special Instruction Form No.

FM055228. Shims are available for the adjustment

of the liner projection. See CYLINDER LINER

PROJECTION in TESTING AND ADJUSTING

for the shim thickness and part number.

6. Remove tooling (B) and (C). Remove the liner.

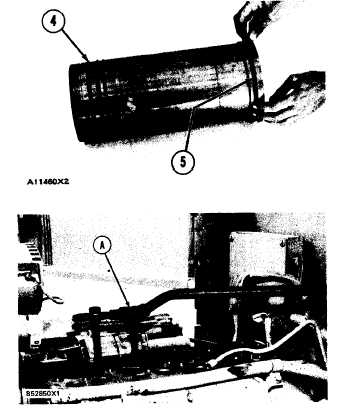

7. Put liquid soap on bottom liner bore in block, on

grooves in lower liner and on O-ring seals (4).

Install O-ring seals on the liner.

8. Put filler band (5) in clean SAE 30 oil for a

moment and install on liner. Install cylinder

liner immediately in the cylinder block (before

TM 5-3805-258-24-2

DISASSEMBLY AND ASSEMBLY

LINERS

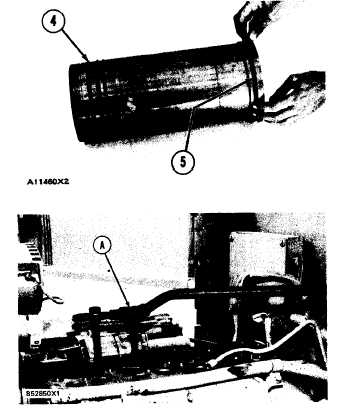

9.

10.

Make sure the mark on liner is in alignment

with the mark on the block. Use tooling (A) to

push the liner into position.

Do Steps 5 through 9 for the remainder of the

cylinder liners.

end by:

a) install pistons

expansion of filler band).

5-141