TM 5-3805-262-20

11-1. BUCKET TILT CYLINDER ASSEMBLIES MAINTENANCE (CONT)

b. Replacement (cont).

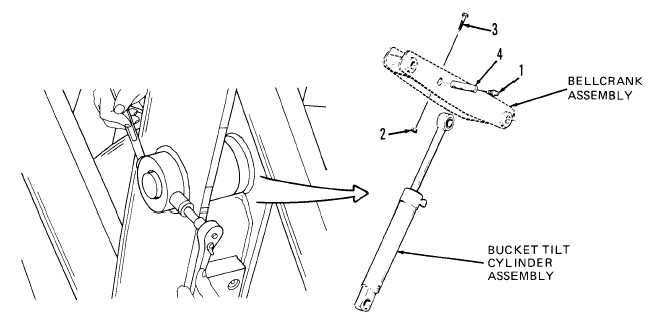

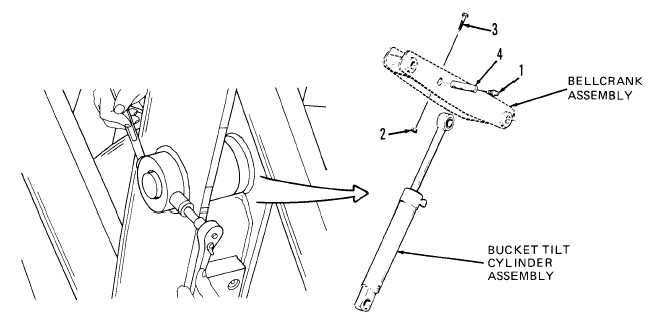

INSTALLATION (SHEET 3 OF 4)

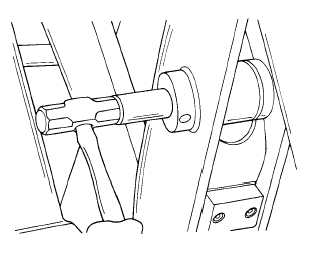

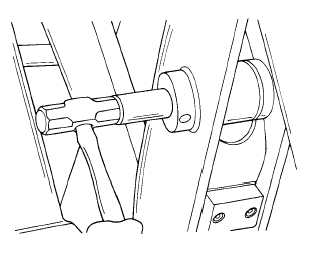

Don’t use your fingers to check alinement in

l o s e a f i n g e r o r s u f f e r s e v e r e i n j u r y t o

obtain medical aid immediately.

(11) Start engine and operate at idle speed.

DUMP position to extend rod of cylinder

f o l l o w i n g s t e p . Y o u c o u ld

d o s o .

If you are injured,

Place BUCKET control lever in

assembly until rod end eye is

alined with holes in bellcrank. Turn off engine.

( 1 2 ) S t a r t p i v o t p i n ( 4 ) i n b e l l -

crank hole. Be sure hole in

pivot pin is alined with cap-

screw hole in bellcrank. Using

hammer, drive pivot pin into

p o s i t i o n .

(13) Apply Loctite 242 (blue) to

threads of capscrew (3) and

l o c k n u t ( 2 ) .

( 1 4 ) I n s t a l l a n d t i g h t e n c a p s c r ew

(3) and lock nut (2). Tighten

to 1000 to 1200 lb-ft.

( 1 5 ) I f n e c e s s a r y , i n s t a l l l u b r i c a -

t i o n f i t t i n g ( 1 ) .

11-10