TM 5-3805-262-20

12-3. LOADER BUCKET ASSEMBLY MAINTENANCE (CONT)

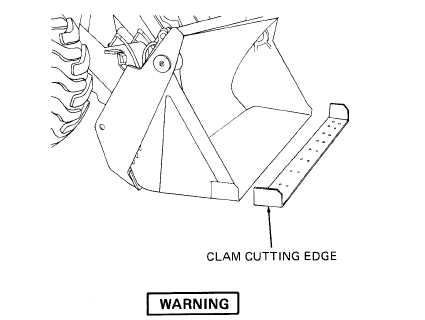

d. Clam Bucket Cutting Edge.

This task covers removal and replacement of clam

bucket cutting edge.

TOOLS: Shop Equipment Welding T16714

C-clamps, four

MATERIALS/PARTS: E-7018 welding rod,

PERSONNEL REQUIRED: Two Construction

quantity as required

Equipment Mechanics M0S 62B

NOTE

PRELIMINARY PROCEDURE: Clam bucket shank assemblies removed (page 12-26)

and alternator wiring disconnected (page 5-10).

REMOVAL (SHEET 1 OF 2)

(1)

Start engine, raise clam bucket to an acceptable working height, and tell

assistant to place supports beneath bucket ensuring that supports do not

interfere with removal of cutting edge.

Wear tinted protective goggles and insulated

acetylene torch and heated parts. Failure to

from flame of torch or serious injury due to

or burned, get medical aid immediately.

gloves when working with

do so could cause blindness

burns. If you are injured

(2)

Using carbon arc rod or an acetylene cutting torch, remove cutting edge

from clam. Keep distortion to a minimum amount while removing cutting

edge.

12-28