TM 5-3805-262-20

12-3. LOADER BUCKET ASSEMBLY MAINTENANCE (CONT)

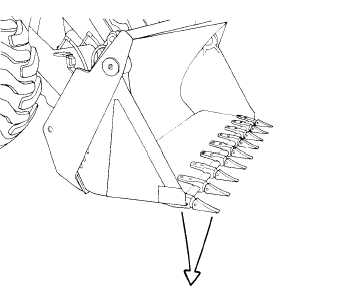

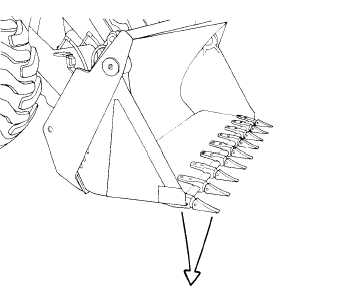

c. Clam Bucket Shank Assemblies.

This task covers removal and replacement of

clam bucket shank (teeth) assemblies.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Hand hammer, 16 ounces

Combination box and open end wrench set

Scratch wire brush

Torque wrench, 1/2 inch drive

Jack stands, two

Automotive Mechanic’s Tool Kit

Socket wrench set, 1/2 inch drive

Drive pin punch, 3/8 inch point

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

PERSONNEL REQUIRED: Two Construction Equipment Mechanics M0S 62B

REMOVAL

(1)

Start engine and raise bucket

to acceptable working height.

(2)

Place acceptable supports under

bucket to support it.

NOTE

I f c o m p l e t e t o o t h a s s e m b l y i s t o be

r e p l a c e d , g o t o s t e p ( 5 ) b e l o w . I f

t o o t h p o i n t o n l y i s t o b e r e p l a c e d,

g o t o s t e p ( 3 ) a n d d i s r e g a r d s t e ps

(5)

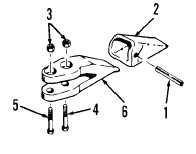

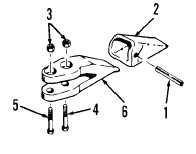

(3)

(4)

(5)

(6)

and (6) .

Using a hammer and punch, drive roll

pin (1) out of tooth point (2).

Remove tooth point (2).

If tooth shank (6) requires replacement,

remove two nuts (3) and capscrews (4 and

5 ).

Remove tooth shank (6).

12-26