TM 5-3805-262-20

3-5. FUEL SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. LOW FUEL PRESSURE (Cont).

Step 7. Bleed air from fuel system (page 4-40).

Tell assistant to crank engine for 30 seconds while you watch pres-

sure gage in tee installed in fuel injection pump feed pump port.

Pressure gage should indicate 20 to 30 psi.

a .

b .

If pressure gage indicates 20 to 30 psi, troubleshooting is com-

pleted; problem was in fuel element or fuel bowl.

Loosen clamps and disconnect hose from barb fittings installed

in filter head and fuel injection pump feed pump.

Disconnect pressure gage from tee.

Remove barb hose connectors and tee installed in filter head and

fuel injection pump feed pump.

Reinstall elbows in filter head and fuel injection pump feed

pump.

Using compressed air, clear any blockage from tube.

Reconnect tube fittings to elbows and tighten securely.

Reinstall engine right side panels (page 9-17).

If pressure gage does not indicate 20 to 30 psi, notify next

higher maintenance level to replace fuel injection pump feed

pump.

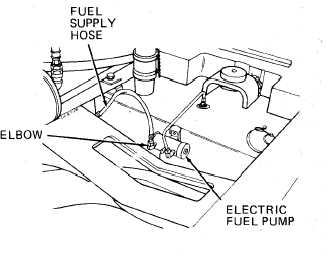

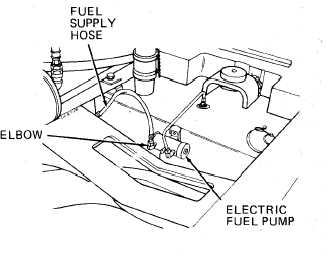

Step 8. Disconnect opposite end of fuel supply hose at fuel tank and remove

fuel supply hose.

Remove elbow from electric fuel

pump.

Install 1/8 NPTF male to 1/4

NPTF female elbow in electric

fuel pump port.

Install zero to 25 psi pressure

gage in elbow (elbow is 1/4

NPTF) .

T e l l a s s i s t a n t t o t u r n i g n i t i on

key switch to on position.

Pressure gage should indicate

3.2 to 9 psi.

T e l l a s s i s t a n t t o t u r n i g n i t i on

key switch to off position.

3-47