TM 5-3805-262-20

3-5. FUEL SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. LOW FUEL PRESSURE (Cont).

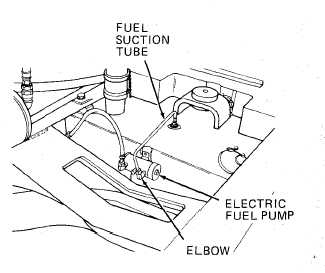

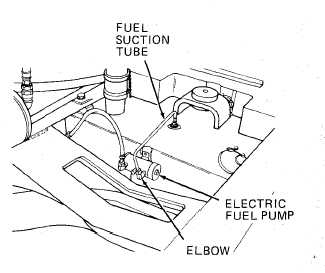

Step 10. At electric fuel pump and fuel tank,

loosen two nuts securing fuel

suction tube.

Disconnect fuel suction tube

from elbow at electric fuel

pump.

C o m p r e s s e d a i r u s e d f o r c l e a n i ng

purposes will not exceed 30 psi. Use

o n l y w i t h e f f e c t i v e c h i p g u a r d i n g

a n d p e r s o n a l p r o t e c t i v e e q u i p m e nt

( g o g g l e s / s h i e l d , g l o v e s , e t c ) .

Failure to do so could cause serious

i n j u r y t o e y e s a n d p o s s i b l e

blindness. If you hurt your eyes or

i f a f o r e i g n o b j e c t i s b l o w n i n t o

y o u r e y e s , s e e k m e d i c a l a t t e n t i o n

immediately.

Use compressed air and clear any blockage from fuel suction tube.

Reconnect fuel suction tube to elbow at electric fuel pump.

Tighten two nuts at electric fuel pump and fuel tank to secure fuel

suction tube.

Tell assistant to turn ignition key switch to on position.

Pressure gage connected to electric fuel pump should indicate 3.2 to

9 p s i.

Tell assistant to turn ignition key switch to off position.

a. If electric fuel pump indicates 3.2 to 9 psi, troubleshooting is

complete; problem was clogged fuel suction tube.

Disconnect pressure gage and elbow from electric fuel pump port.

Reinstall elbow and fuel supply hose between elbow and fuel in-

jection pump feed pump.

Reinstall engine right side panels (page 9-17).

b. If pressure gage still does not indicate 3.2 to 9 psi, go to

step 11 below.

3-49