TM 5-3805-262-20

5-4 INSTRUMENT PANELS MAINTENANCE (CONT)

b. Right-hand Instrument Panel (cont).

INSPECTION, TESTING, AND REPAIR (SHEET 2 OF 5)

(3)

( a )

(b)

(c)

(d)

(e)

( f )

(g)

(h)

(4)

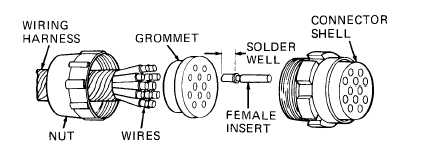

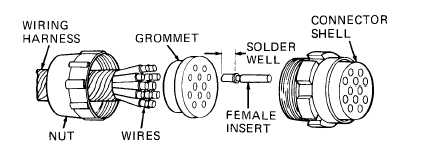

Inspect vehicle lights switch connector (19) wires for cracked or broken

insulation, broken wire strands, or broken connector inserts. Repair

cracked or broken insulation by applying insulation tape to area. If bro-

ken wire strands or broken connector inserts are seen, repair using parts

f r o m e l e c t r i c a l r e p a i r t o o l k i t a s f o l l o w s:

Loosen and remove nut from connector shell and slide over wiring harness

as shown below.

Pull grommet with inserts from connector shell.

Pull insert with wire end from grommet.

Cut wire as close to insert as possible.

Strip wire insulation to depth of insert solder well, position wire end

in solder well of insert, and solder.

Push insert with wire into grommet.

Aline inserts with holes in connecter shell and push grommet with in-

s e r t s i n t o c o n n e c t o r s h e l l u n t i l s e a t e d.

Slide nut over wiring harness and install on connector shell .

Inspect fuseholder (7) for cracks, breaks, distortion, or other damage.

Replace fuseholder by cutting wires as close to fuseholder halves as pos-

s i b l e,

stripping 1/4 inch insulation from end of wires, then splicing new

fuseholder wires to existing wires using insulated crimp connectors.

5-56