TM 5-3805-262-20

CLEANING

Dry cleaning solvent P-D-680 used to clean parts is toxic and flammable.

W e a r p r o t e c t i v e g o g g l e s a n d g l o v e s a n d u s e o n l y i n a w e l l v e n t i l a t e d

a r e a . A v o i d c o n t a c t w i t h s k i n ,

e y e s a n d c l o t h e s a n d d o n ’ t b r e a t h e

v a p o r s .

Do not use near open flame or excessive heat and don’t smoke

when using it. Failure to do so could cause serious injury. If you be-

c o m e d i z z y w h i l e u s i n g c l e a n i n g s o l v e n t , g e t f r e s h a i r a n d m e d i c a l

a t t e n t i o n i m m e d i a t e l y .

If contact with skin or clothes is made, flush

with large amounts of water.

I f c o n t a c t w i t h e y e s i s m a d e , w a s h e y e s

with water and get medical aid immediately.

a. Wipe exterior of micro switches (5 and 14) using clean cloth moistened with

cleaning solvent P-D-680. Dry using clean cloths,

b. Clean wire insulation using clean cloth moistened with detergent. Dry using

c l e a n c l o t h.

c. Clean terminals using clean cloth moistened with isopropyl alcohol.

d. Clean all other metallic parts using clean cloth moistened with cleaning sol-

vent P-D-680. Dry using clean cloths.

INSPECTION, TESTING, AND REPAIR

a. Inspect ground wire (22) and wiring harnesses (19 and 27) wires for cracked or

broken insulation or broken wire strands at connection to terminals. Repair

cracked or broken insulation by applying insulation tape to area. If broken

wire strands are seens replace ground wire (22) or wiring harness (19 or 27).

b. Inspect brown-white and blue-white wire terminals (26) and front wiring har-

ness terminal (23) wires for cracked or broken insulation or broken wire

s t r a n d s a t c o n n e c t i o n t o t e r m i n a l s . R e p a i r c r a c k e d o r b r o k e n i n s u l a t i o n b y

applying insulation tape to area. If broken wire strands are seen, cut wire as

close to terminal as possible. Strip 1/4 inch insulation from end of wire tak-

ing care not to cut through wire then crimp new terminal securely onto wire.

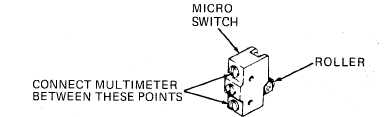

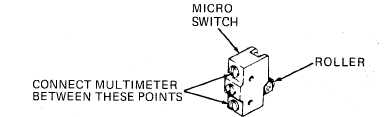

c. Inspect micro switches (5 and 14) for cracks, breaks, damaged threads, seized

r o l l e r , d i s t o r t i o n, or other damage. Connect multimeter between micro switch

COM and NC terminals as shown below and watch multimeter. When you press

roller with thumb, switch should click and multimeter should indicate no

c o n t i n u i t y ( o p e n c i r c u i t ) . When you release roller, switch should click and

multimeter should indicate continuity. If any of the above conditions are seen

or if proper multimeter indications are not

obtained, replace micro switch.

d. Inspect remaining parts for cracks, breaks, dis-

tortion, or damaged threads; replace as necessary.

5-71