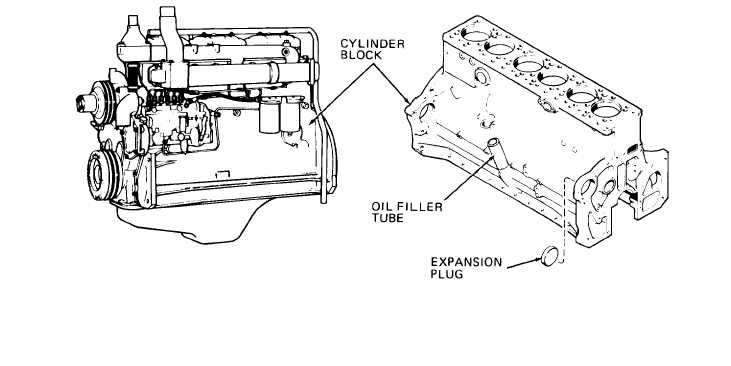

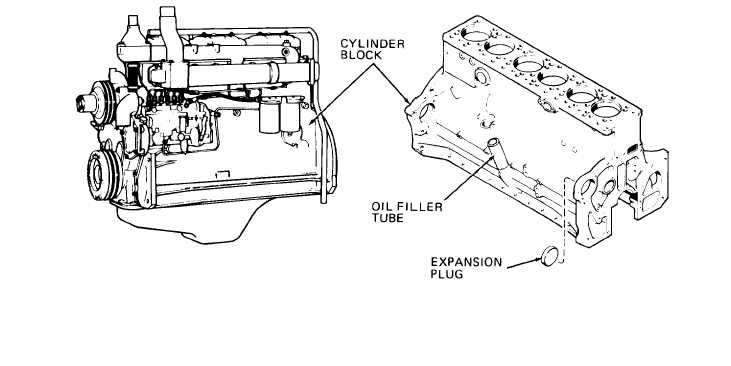

INSPECTION/REPAIR

(a) Inspect expansion plug for cracks, distortion, or other

TM 5-3805-262-34

damage. Punch a

hole in center of defective expansion plug, pry plug from cylinder

block, and discard plug. Apply non-hardening sealant to outer edge of

new expansion plug, position in cylinder block bore, and tap into posi-

tion using hammer.

(b) Inspect oil filler tube for cracks, dents, and damaged threads. Notify

general support maintenance if any of these conditions are seen.

(c) Inspect cylinder block for cracks, excessive wear, erosion, distortion,

or damaged threads. Chase damaged threads using the proper size tap. If

threads do not clean up or any of the above conditions are seen, notify

general support maintenance.

3-41