TM 5-3805-262-34

3-1. ENGINE MAINTENANCE (CONT)

d. Cylinder Block (Cont).

(2)

CLEANING

Tachometer Drive (Cont).

AND INSPECTION (SHEET 2 OF 2)

Compressed air used for cleaning purposes will not exceed 30 psi. Use

only with effective chip guarding and personal protective equipment

(goggles/shield, gloves, etc). Failure to do so could cause serious

injury to eyes and possible blindness. If you hurt your eyes or if a

foreign object is blown into your eyes, seek medical attention

immediately.

(a) Immerse tachometer drive in cleaning

solvent P-D-680 and slowly move up

and down to thoroughly clean inte-

rior. Dry using compressed air.

After drying, immerse tachometer

drive in clean engine oil and rotate

gear with fingers to lubricate

bushings.

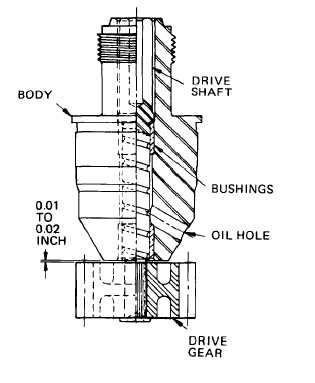

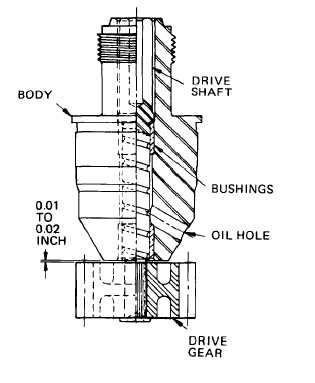

(b) Inspect tachometer drive for cracked

body, chipped or broken drive gear

teeth, excessively worn drive shaft

or bushings, blocked oil hole, or

thread damage. Rotate drive gear

with fingers and check that it turns

smoothly. Measure drive gear clear-

ance using thickness gage. Replace

tachometer drive as an assembly if

clearance is not 0.01 to 0.02 inch

or if any of the above conditions

are seen.

INSTALLATION

(a) Lower tachometer drive into cylinder block bore. Mesh tachometer drive

and engine gears, and rotate tachometer drive body until oil hole faces

away from engine.

(b) Using soft hammer, carefully tap tachometer drive into bore until flush

with cylinder block.

(c) Connect tachometer drive cable end to tachometer drive. Tighten cable

nut using pliers.

(d) Install engine left front side panel (refer to TM 5-3805-262-20).

3-44