TM 5-3805-262-34

3-24. TILT CYLINDER ASSEMBLIES MAINTENANCE (CONT)

REASSEMBLY (SHEET 2 OF 2)

q.

r.

s.

t.

u.

v.

w.

x.

y.

z.

Install smaller bore piston (4) and packing assembly (5) on rod (16). Put

ring (6) in place next to piston then install piston (3) next to ring.

Clean any lubricating oil from threads of capscrew (1) and internal threads

on rod (16). Apply retaining compound to threads of capscrew.

Install washer (2) and capscrew (1) to secure piston assembly.

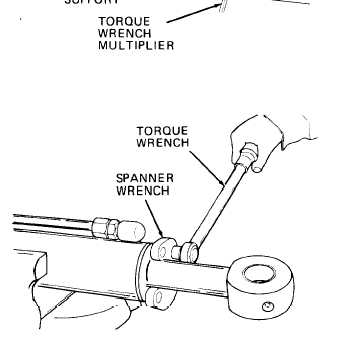

Tighten capscrew to 1000 to 1200 lb-ft. Use torque wrench

multiplier as necessary.

Remove rod (16) from vise.

In following step, don’t

overtighten vise. Overtightening

will distort cylinder tube (19).

Put cylinder tube (19) in vise.

Lubricate cylinder tube (19) inside wall

and piston assembly (3 thru 6) using

clean lubricating oil.

Start rod (16) straight into cylinder

tube (19).

Screw gland (14) into cylinder tube

(19). Don’t tighten gland.

Push rod (16) farther into cylinder

tube (19) using soft hammer or steel

rod inserted through rod eye.

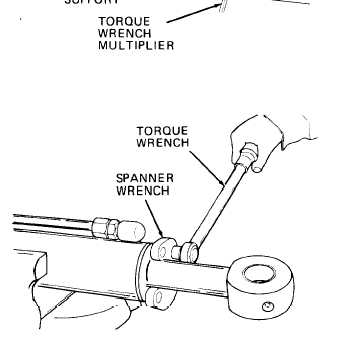

Install gland (14) into cylinder tube

(19) until gland comes in contact

with cylinder tube. Using spanner

wrench, tighten gland to 200 to 300

lb-ft.

aa. Install tilt cylinder assemblies

(refer to TM 5-3805-262-20).

3-730