TM 5-3805-262-34

3-25. BUCKET HEIGHT CONTROL MAINTENANCE

This task covers removal, disassembly, cleaning, inspection, reassembly, and instal-

lation of bucket height control.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Hand hammer, 16 ounces

Combination box and open end wrench set

Safety glasses

Socket wrench set, 3/8 inch drive

Drive pin punch, 3/8 inch point

Micrometer, zero to 5 inches

Bore gage

Rod or sleeve, one inch diameter

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Detergent (Appendix C, item 4)

Paint (Appendix C, item 22)

PERSONNEL REQUIRED: TWO Construction Equipment Mechanics MOS 62B

REFERENCE: TM 5-3805-262-20

NOTE

PRELIMINARY PROCEDURE: Bucket height control micro switch and clamp

removed (refer to TM 5-3805-262-20).

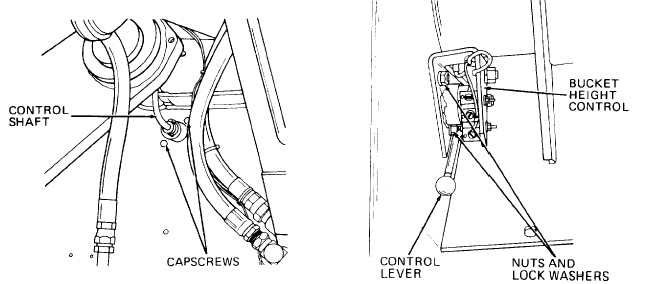

REMOVAL

a.

While assistant holds capscrews at side of loader using socket wrench, loos-

en and remove two nuts and lock washers.

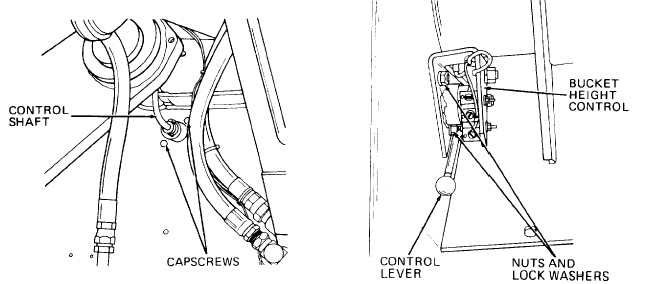

b.

Support bucket height control and tell assistant to remove two capscrews.

c.

Remove bucket height control from side of chassis. Do this by maneuvering

control shaft through hole in front chassis into cab. If necessary, move

control lever to position control shaft to make removal easier.

3-732