TM 5-3805-262-34

2-5. FUEL SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. FUEL INJECTION PUMP NOT OPERATING PROPERLY (Cont).

Step 23. With control lever locked in position as in step 22 above, operate

pump at 375 rpm and watch rack travel dial indicator. Dial indicator

should move 0.335 to 0.343 inch.

Watch rack travel dial indicator and operate fuel injection pump at

100 rpm.

Rack should travel a minimum of 0.749 inch as indicated by dial in-

dicator.

Watch rack travel dial indicator and slowly increase rpm to 375 rpm.

Dial indicator should move counterclockwise and indicate 0.335 to

0.343 inch.

a. If rack movement is as specified above, go to step 24 below.

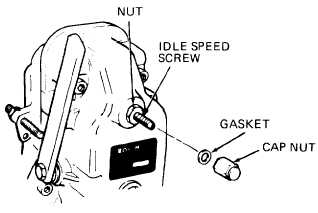

b. If rack movement is not as specified above, remove gasket and

cap nut and turn supplementary idle speed screw clockwise to in-

crease rack or counterclockwise to decrease rack. Repeat this

step to recheck rack movement.

Step 24. With control lever locked

pump at 375 rpm and check

rack movement of 0.335 to

in position as in step 22 above, operate

that rack travel dial indicator indicates

0.343 inch.

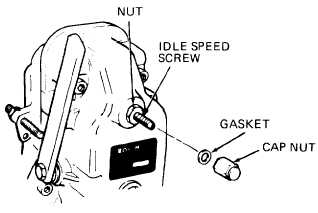

Adjust idle speed screw until slight resistance is felt.

Release control lever.

Adjust idle speed screw until governor setting protractor scale in-

dicates 25 degrees.

Operate fuel injection pump at 375 rpm.

Set test bench for 1000 strokes.

Take a fuel draw.

Fuel delivery from each cylinder should be 18.5 to 22.5 cc/1000

strokes at 375 rpm.

2-69