TM 5-3805-262-34

2-5. FUEL SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. FUEL INJECTION PUMP NOT OPERATING PROPERLY (Cont).

Step 16.

Step 17.

Step 18.

With control lever against adjustment screw, increase fuel injection

pump speed to 1300 rpm.

Check that rack travel dial indicator indicates 0.012 to 0.067 inch

rack travel.

a. If dial indicator indicates 0.012 to 0.067 inch, go to step 17

below.

b.

If dial indicator does not indicate 0.012 to 0.067 inch, make

coarse adjustments by adjusting swivel lever adjusting screw

(one click counterclockwise increases rack travel 0.0098 inch).

Make fine adjustments by adjusting no load governed speed ad-

justment screw.

Operate fuel injection pump at 600 rpm.

Watch rack travel dial indicator and increase speed to 1300 rpm.

Dial indicator should hold steady (not fluctuate) within 0.008 inch.

a. If dial indicator holds steady within 0.008 inch, go to step 18

below.

b. If dial indicator does not hold steady within 0.008 inch, disas-

semble governor (page 3-173). Check for bent guide lever, ten-

sioning lever, or swivel lever.

Lock control lever against no

load governed speed adjustment

screw.

Set test bench for 1000

strokes.

Operate fuel injection pump at

1100 rpm.

Take a fuel draw.

Fuel delivery from each cylin-

der should be 89 to 95 cc/1000

strokes.

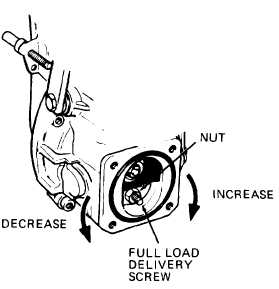

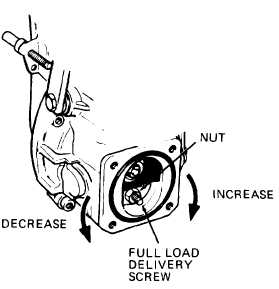

a. If fuel delivery from each

cylinder is 89 to 95 cc/

1000 strokes, tighten nut

on full load delivery screw

to lock adjustment. Record

rack travel dial indicator

reading and go to step 19

below.

2-65