TM 5-3805-290-10

RETURN TO CARRY ADJUSTMENT - CONTINUED

0019 00

ADJUSTMENT - CONTINUED

N OT E

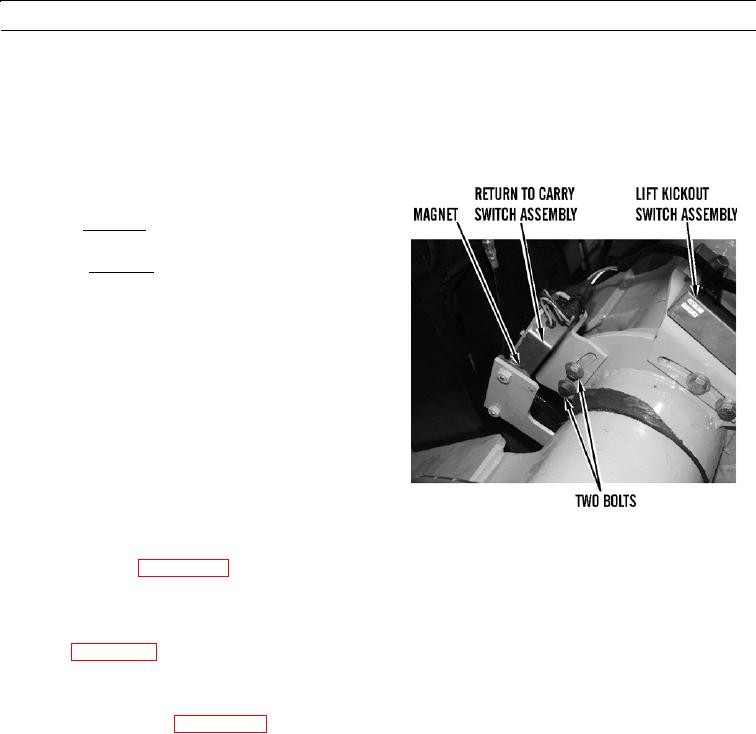

There are two switch assemblies mounted at base of loader arm. One is for lift kickout; the other is for

return to carry kickout. The return to carry kickout switch assembly is mounted furthest from the cab.

7.

Access return to carry kickout switch assembly from left side of machine.

8.

Loosen two bolts and move switch assembly to posi-

tion observed in step 4.

a.

If increasing return to carry kickout height, move

switch assembly clockwise (to the right) or back.

b.

If decreasing return to carry kickout height,

move switch assembly counterclockwise (to the

left) or forward.

9.

Tighten two bolts to secure switch assembly.

427-B0580

10.

Test adjustment as follows:

a.

Start engine (WP 0005 00).

b.

Move joystick to lift kickout detent position. When bucket reaches preset lift kickout height, move joystick control

to RETURN TO CARRY detent position.

c.

When bucket reaches preset return to carry kickout height, joystick control lever should return to HOLD position

(WP 0004 00). Loader arm will stop moving.

d.

Repeat steps 2 thru 10 until adjustment is correct.

e.

Lower work tool to ground.

f.

Shut down engine (WP 0005 00).

END OF WORK PACKAGE

0019 00-2