TM 5-3805-290-23-1

TRANSMISSION TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0014 00

N OT E

For a better understanding of each system, review the appropriate section in Theory of Operation (WP 0003

These procedures may give direction to replace wiring harnesses. However, limited repair of wiring harnesses

is authorized. Refer to Electrical General Maintenance Instructions (WP 0022 00) for the correct repair proce-

dures.

TRANSMISSION CLUTCH FILL CALIBRATION

0014 00

14

WARN I N G

Use extreme caution when performing this test. Keep nonessential personnel away from area. Sudden

movement of machine may cause injury or death to personnel.

CAU T I ON

DO NOT connect or disconnect hose fittings to or from quick-disconnect nipples when there is pressure in

system. This will prevent damage to seals in fitting.

N OT E

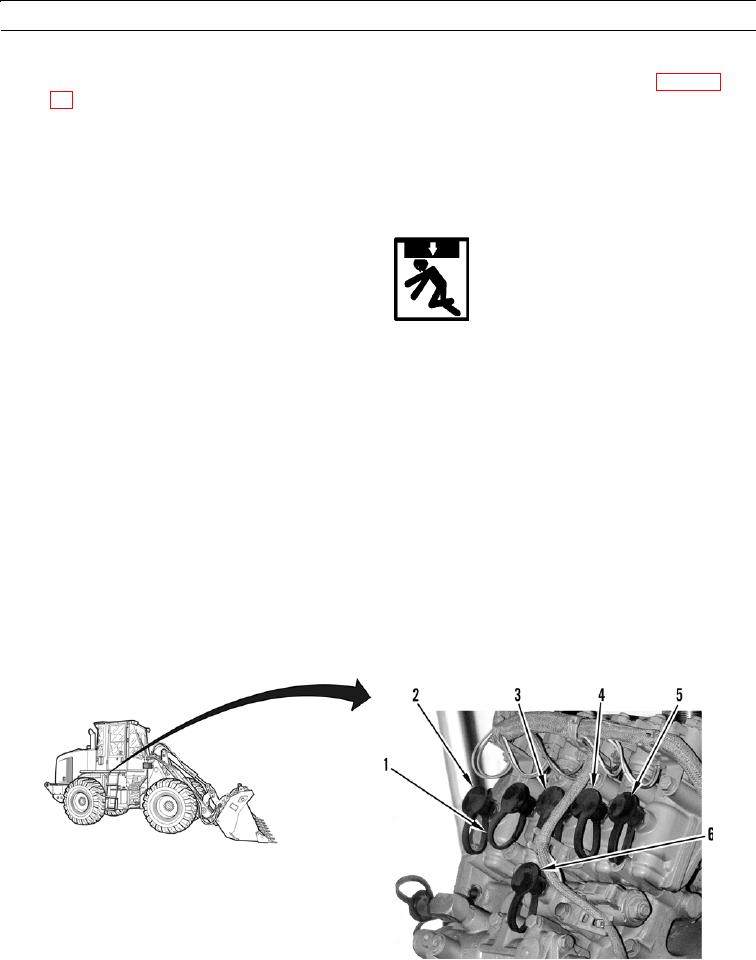

Machine is equipped with these modulating valves and clutches:

a.

Modulating valve for clutch 1 (1) (forward low)

b.

Modulating valve for clutch 2 (2) (forward high)

c.

Modulating valve for clutch 3 (3) (reverse)

d.

Modulating valve for clutch 4 (4) (second speed)

e.

Modulating valve for clutch 5 (5) (third speed and fourth speed)

f.

Modulating valve for clutch 6 (6) (first speed)

427-B0919