2

TM 5-3805-290-23-2

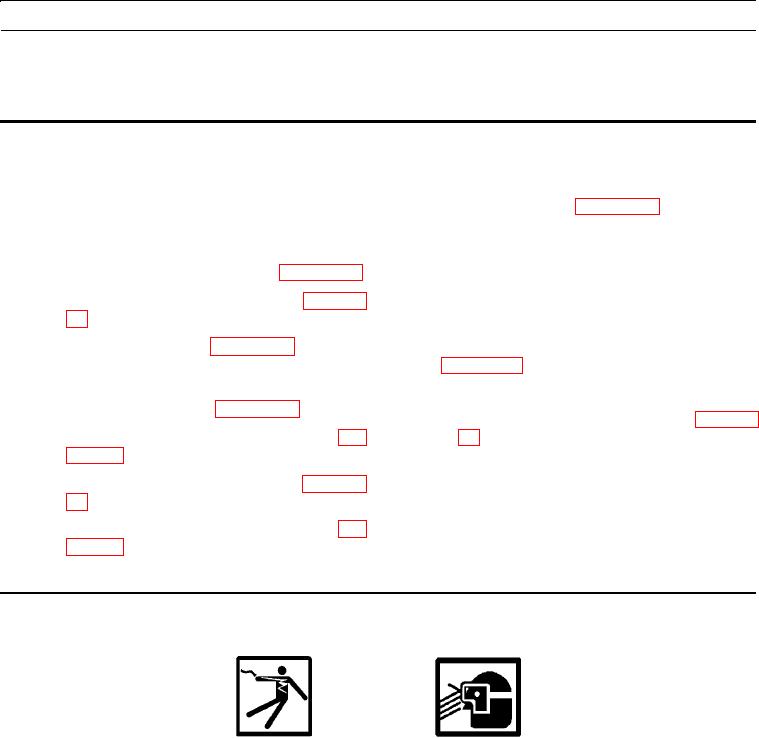

RIDE CONTROL PRESSURE SWITCH REPLACEMENT

THIS WORK PACKAGE COVERS

Removal, Installation

INITIAL SETUP

Maintenance Level

Materials/Parts - Continued

Rag, wiping (Item 41, WP 0206 00)

Unit

O-ring

Tools and Special Tools

Personnel Required

Tool kit, general mechanic's (Item 96, WP 0205 00)

MOS 62B, Construction Equipment Repairer

Shop equipment, common no. 1 (Item 77, WP 0205

References

TM 5-3805-290-10

Wrench, torque (Item 102, WP 0205 00)

Materials/Parts

Equipment Conditions

Cap set, protective (Item 8, WP 0206 00)

Ride control accumulator guard removed (WP 0107

Oil, lubricating, OEA-30, Arctic (Item 32, WP

Drawings Required

Oil, lubricating, OE/HDO-5/40 (Item 34, WP 0206

TM 5-3805-290-23P, Figure 51

Estimated Time to Complete Task

Oil, lubricating, OE/HDO-15/40 (Item 35, WP

1.0 hr

WARN I N G

Ensure battery disconnect switch is in OFF position before performing this task. Failure to follow this warn-

ing may result in injury to personnel or damage to equipment.

To prevent injury to personnel, wear protective eye covering and gloves.

C AU T I O N

Wipe area clean around sensor during removal. Plug opening after removing. Contamination of system

could result in premature failure.

N OT E

Use a container to catch any fluid that may drain from hoses or system. Dispose of fluid IAW local policy

and ordinances. Ensure all spills are cleaned up.