TM 5-3805-290-23-2

RIDE CONTROL ACCUMULATOR MAINTENANCE - CONTINUED

0127 00

TESTING AND CHARGING - CONTINUED

Nitrogen Charging Procedure - Continued

9.

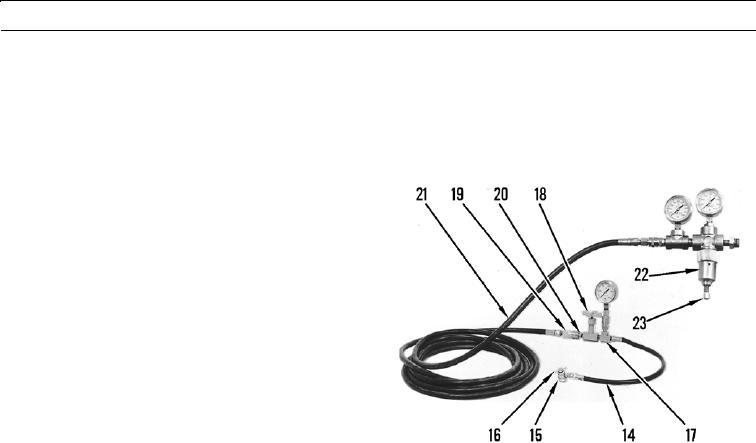

Turn handle (16) on nitrogen charging chuck (15) fully counterclockwise.

10.

Connect nitrogen charging chuck (15) to nitrogen charging valve (12).

11.

Connect hose assembly (14) between nitrogen charg-

ing chuck (15) and T (17).

12.

Install needle valve (18) on one connecting point of T

(17).

13.

Install gage in remaining open port on T (17).

14.

Install coupling assembly (19) in open port of needle

valve (18).

15.

Install nipple (20) on one end of hose assembly (21).

16.

Place open end of hose assembly (21) away from work

area.

427-B1029-1

17.

Open needle valve (18) and turn handle (16) on nitrogen charging chuck (15) fully clockwise.

18.

Raise lift arms fully to momentarily relieve nitrogen pressure charge (TM 5-3805-290-10).

19.

Close needle valve (18).

20.

Lower work tool to ground (TM 5-3805-290-10).

21.

Move lift control lever to FLOAT position (TM 5-3805-290-10).

22.

Connect open end of hose assembly (21) to regulator assembly (22).

23.

Install gage in port directly above regulator.

24.

Install gage in remaining port next to regulator assembly (22).

25.

Install regulator assembly (22) on nitrogen charging valve (12).

26.

Adjust screw (23) on regulator assembly (22) to set pressure on gage to 355 25 psi (2,446 172 kPa).

N OT E

To ensure accumulator nitrogen charge is correct, accumulator piston must be at bottom of accumulator

cylinder. Nitrogen pressure varies with temperature. To obtain most accurate nitrogen charge, temperature

of accumulator should equal outside air temperature. However, temperature of accumulator could be

higher than outside air temperature in some cases. If this is the case, temperature of accumulator should be

used instead of outside air temperature.

27.

Open needle valve (18).

28.

Nitrogen pressure should appear on gage in 10 to 20 seconds.

0127 00-9