TM 5-3805-290-23-2

FUEL INJECTOR ASSEMBLY REPLACEMENT - CONTINUED

0163 00

TESTING - CONTINUED

Fuel Injector Nozzle and Seat Test

1.

Connect fuel injector nozzle (2) to tooling as shown (see Back Leakage Test in this work package).

2.

Position fuel injector nozzle (2) so that fuel spray is directed into coupling and can.

3.

Pump pressure of nozzle tester to approximately 3,525 psi (24,304 kPa). A drop of calibrating fluid should NOT form

on tip of fuel injector nozzle for at least ten seconds. Light dampness is acceptable. If results of tests are not acceptable,

clean fuel injector nozzle. If fuel leakage occurs after cleaning, fuel injector nozzle must be replaced.

Spray Pattern Test

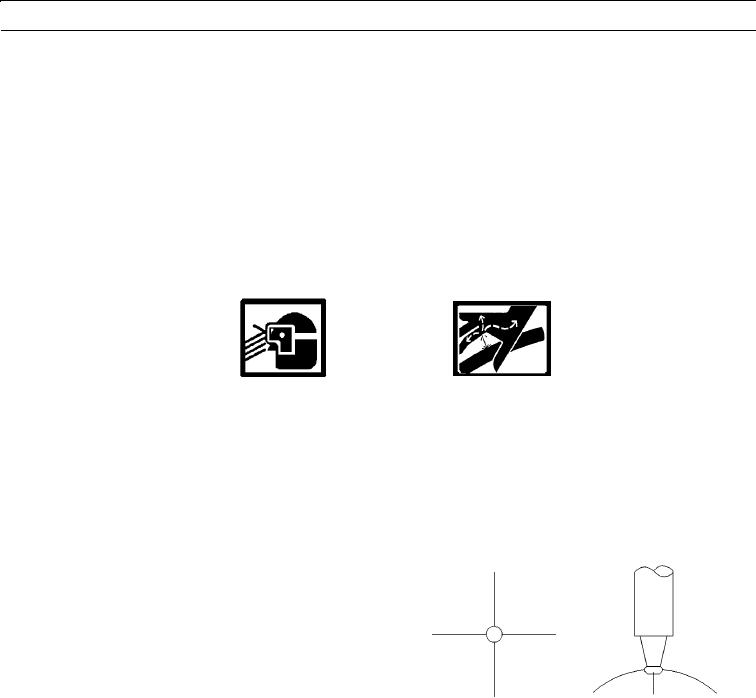

WARN I N G

Ensure eye protection is worn at all times during testing. When fuel injector nozzles are tested, test

fluid travels through orifices of nozzle tips at high pressure. Under this amount of pressure, test fluid

can pierce skin and cause injury to personnel. Always keep tip of fuel injector nozzle pointed away

from personnel and into fuel collector and extension. Failure to follow this warning may result in

injury to personnel.

1.

Connect fuel injector nozzle (2) to tooling as shown (see Back Leakage Test in this work package).

2.

Position fuel injector nozzle (2) so that fuel spray is directed into coupling and can.

3.

Close gage protector valve and shutoff valve.

4.

Open pump isolator valve.

5.

Quickly pump nozzle tester and look at spray pattern

when fluid begins to flow through orifices of fuel

injector nozzle (2).

6.

Spray, which flows from all injector orifices, must

have same pattern. Fuel injector nozzle (2) is faulty if

there is difference in vertical or horizontal spray pat-

terns. Refer to correct spray pattern in illustration.

427-B0097

END OF WORK PACKAGE

0163 00-8