TM 5-3805-290-23-2

FUEL INJECTOR ASSEMBLY REPLACEMENT - CONTINUED

0163 00

TESTING - CONTINUED

Back Leakage Test

WARN I N G

Ensure eye protection is worn at all times during testing. When fuel injector nozzles are tested, test

fluid travels through orifices of nozzle tips at high pressure. Under this amount of pressure, test fluid

can pierce skin and cause injury to personnel. Always keep tip of fuel injector nozzle pointed away

from personnel and into fuel collector and extension. Failure to follow this warning may result in

injury to personnel.

1.

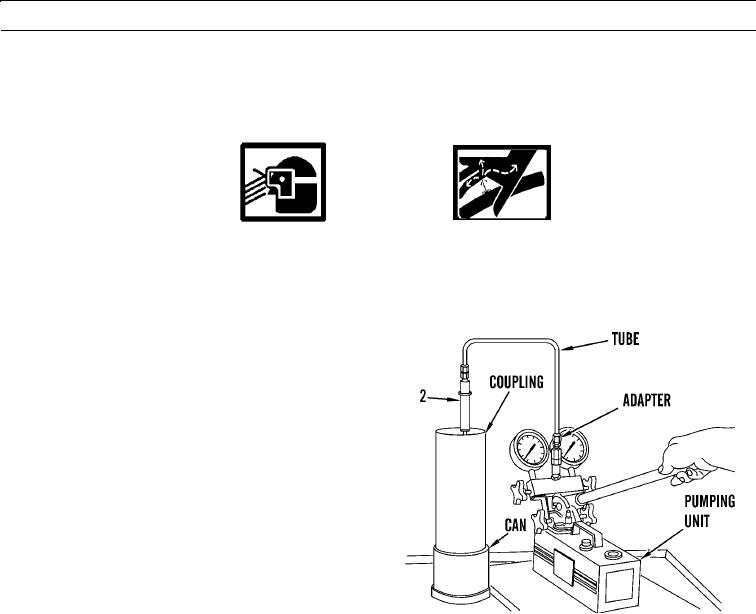

Connect fuel injector nozzle (2) to tooling as shown.

2.

Position fuel injector nozzle (2) so that fuel spray is

directed into coupling and can.

3.

Pump pressure to 3,525 50 psi (24,304 340 kPa).

4.

Release handle. When pressure begins to decrease,

note time required for pressure to decrease to approxi-

mately 0 psi (0 kPa). If fuel injector nozzle (2) is not

faulty, time will not be less than 5 seconds or more

than 45 seconds.

427-B0096

5.

Look for any leakage. If leaks are visible, make sure that components are tightened to correct torque. Replace fuel injec-

tor nozzle if there is excessive fuel leakage.

N OT E

DO NOT overtighten components in order to stop leakage. Instead, a pressure test on fuel injector

nozzle must be conducted. Repeat Pressure Test procedure in this work package. This test may force

any foreign particles out of nozzle.

6.

If pressure decreases to 0 psi (0 kPa) in less than 5 seconds, too much fuel is leaking around valve needle. Valve needle

or fuel injector nozzle must be replaced to correct problem.

0163 00-7