TM 5-3805-290-23-2

FUEL INJECTOR ASSEMBLY REPLACEMENT - CONTINUED

0163 00

INSTALLATION - CONTINUED

CAU T I ON

DO NOT rotate fuel injector nozzle after installation. The seal made by antiseize compound may

break. A broken seal may allow leakage past seat of fuel injector nozzle.

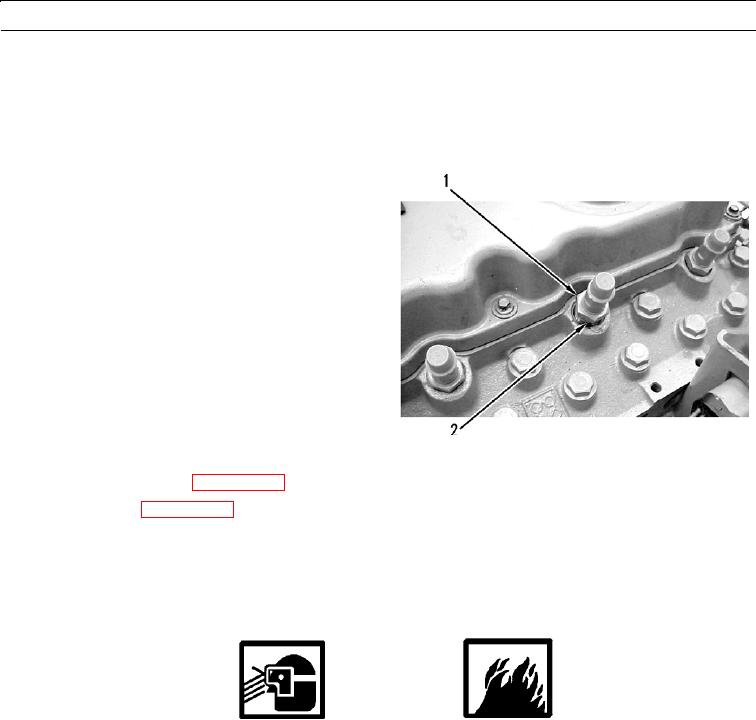

6.

Tighten threaded nut (1) to 22 lb-ft (30 Nm). Remove

any excess antiseize compound from fuel injector noz-

zle (2).

427-B0057

7.

Connect fuel injector lines (WP 0030 00).

8.

Prime fuel system (WP 0029 00).

9.

Run engine and verify correct operation of fuel injector nozzles (TM 5-3805-290-10).

10.

Shut down engine (TM 5-3805-290-10).

TESTING

WARN I N G

Ensure eye protection is worn at all times during testing. When fuel injection nozzles are tested, test fluid

travels through orifices of nozzle tips at high pressure. Under this amount of pressure, test fluid can

pierce skin and cause injury to personnel. Always keep tip of fuel injection nozzle pointed away from

personnel and into fuel collector and extension. Failure to follow this warning may result in injury to

personnel.

DO NOT perform fuel system checks, inspections, or maintenance while smoking or near fire, flames, or

sparks. Fuel may ignite, causing injury or death to personnel or damage to equipment.

CAU T I ON

Extra care should be taken when handling fuel injector nozzles in order to prevent damage to nozzle

tip. A scratch or burr can cause needle leakage or spray distortion. Dirt in orifices of nozzle tip can

damage engine components. Dirt can also distort spray pattern of nozzle.

0163 00-4