TM 5-3805-290-23-2

FUEL INJECTOR ASSEMBLY REPLACEMENT - CONTINUED

0163 00

TESTING - CONTINUED

Pressure Test

WARN I N G

Ensure eye protection is worn at all times during testing. When fuel injector nozzles are tested, test

fluid travels through orifices of nozzle tips at high pressure. Under this amount of pressure, test fluid

can pierce skin and cause injury to personnel. Always keep tip of fuel injector nozzle pointed away

from personnel and into fuel collector and extension. Failure to follow this warning may result in

injury to personnel.

N OT E

Bench test fuel injector nozzles at temperature range of 64 to 70F (18 to 21C).

1.

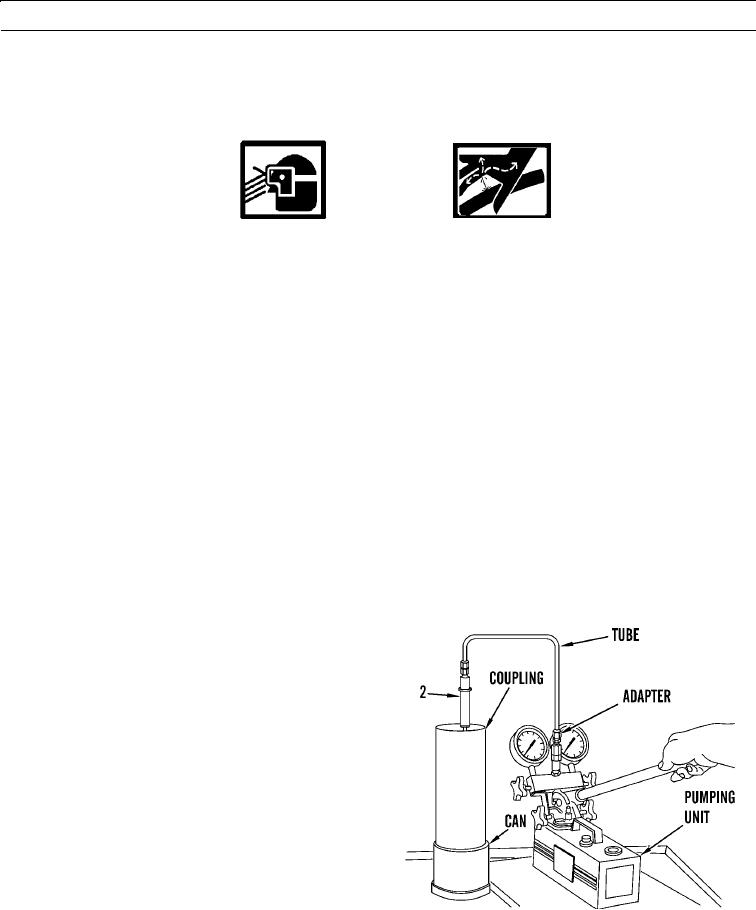

Connect fuel injector nozzle (2) to tooling as shown.

a.

Spray from fuel injector nozzle must be directed into coupling and can.

b.

Opening pressure for injectors is 3,675 50 psi (25,338 345 kPa).

c.

If opening pressure is not within range, fuel injector nozzle must be replaced.

d.

Use clean calibration fluid when fuel injector nozzles are tested.

2.

Close gage protector valve. Close shutoff valve. Open pump isolator valve. In order to flush fuel injection nozzle, oper-

ate nozzle tester for 10 to 15 strokes at a rate of approximately 60 strokes per minute.

3.

Open gage protector valve. Slowly increase pressure until valve in fuel injector nozzle (2) opens. Note highest pressure

indication on dial indicator before pointer moves to 0 psi (0 kPa). This highest pressure indication is opening pressure of

fuel injector nozzle.

N OT E

Opening pressure is defined when valve

needle is lifted from valve seat.

4.

If opening pressure is not within range of 3,675 50

psi (25,338 345 kPa), fuel injector nozzle (2) must

be replaced.

427-B0096

0163 00-6