TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

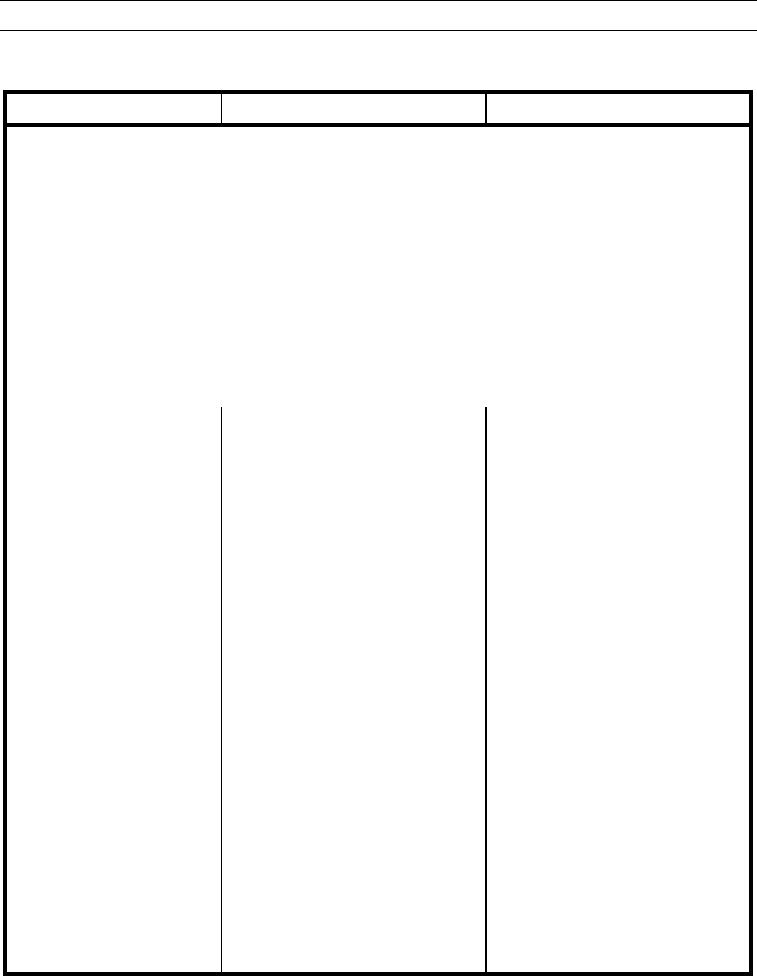

Table 8. AC System Troubleshooting.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

N OT E

When ambient temperature is above 70F (21C), a lo pressure gage reading of 10 to 20 psi (70 to 138

w

kPa) is a normal operating pressure for AC system. Also, when ambient temperature is above 70F

(21C), a high pressure gage reading of 120 to 190 psi (820 to 1,300 kPa) is a normal operating pressure

for AC system. In very hot weather, low pressure readings and high pressure readings will be at high

end of normal operating range. In cooler weather, low pressure reading will be in middle to low end of

normal operating range, while high pressure reading will be low. For correct gage reading in relation

to ambient temperature condition, refer to table below. This table is only for reference.

All pressures are given as a guide only. Weight isonly absolute means of determining proper refriger-

ant charge. Improper refrigerant charge will cause premature failure of compressor.

Unless directed otherwise, all tr ubleshooting listed requires that pressure gages be connected (WP

o

0222 00) to compare system pressures with table below.

Ambient temperature is above70F (21C) in all malfunctions.

PRESSURE RANGE

High Pressure Test Fitting (Pressure May

Ambient Air Temperature

Low Pressure Test Fitting (Pressure Before

Be Slightly Higher in Very Humid

Clutch Disengagement)

Conditions and Lower in Very Dry

Conditions)

70F (21C)

120 to 190 psi (820 to 1,300 kPa)

10 to 20 psi (70 to 138 kPa)

80F (27C)

140 to 210 psi (950 to 1,450 kPa)

10 to 25 psi (70 to 173 kPa)

90F (32C)

170 to 240 psi (1,175 to 1,650 kPa)

15 to 30 psi (105 to 210 kPa)

100F (38C)

190 to 270 psi (1,300 to 1,850 kPa)

15 to 30 psi (105 to 210 kPa)

110F (43C)

210 to 300 psi (1,450 to 2,075 kPa)

15 to 30 psi (105 to 210 kPa)

1. Check blend door for movement.

1. If blend door opens and closes

1.

Temperature of Air Flow is

(a) Turn battery disconnect and

properly, go to Test 6.

Partially Cool.

engine start switches to ON

2. If blend door does not appear to open

position (TM 5-3805-291-10).

and close properly, go to Test 2.

(b) While moving the temperature

control switch back and forth

between full hot and full cold,

listen for blend door movement.

2. Check power to blend door actuator.

1. If voltage is present, go to Test 3.

(a) Disconnect wiring harness from

2. If voltage is not present, there is an

blend door actuator (WP 0052 00).

open circuit between power converter

(b) Turn battery disconnect and

and blend door actuator. Replace

engine start switches to ON

wiring harness in question (WP 0195

position (TM 5-3805-291-10).

00 thru WP 0201 00).

(c) Measure voltage between blend

door actuator pin A, circuit 135

(BU), harness side and ground.