TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

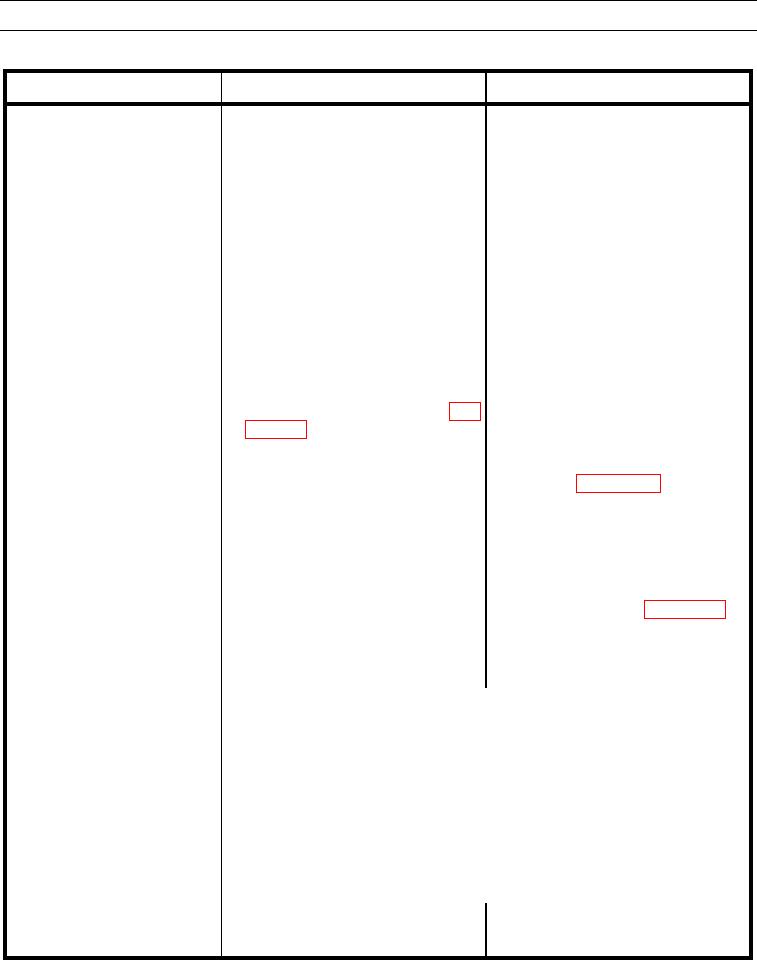

Table 8. AC System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

6. Check low and high pressure gage

1. If both readings are below normal, go

1.

Temperature of Air Flow is

to Test 7.

during operation AC.

Partially Cool - Continued.

2. If low pressure gage reading is normal

but high pressure gage reading bounces

or reading is unsteady, go to Test 8.

3. If low pressure gage reading is below

normal but high pressure gage reading

is normal to below normal range, go to

Test 9.

4. If low pressure gage reading does not

change, pressure gage reading is at high

end of normal range, go to Test 12.

5. If low pressure gage reading is above

normal, high pressure gage reading is

below normal, and system is fully

charge, go to Test 13.

7. Perform Refrigerant Leakage Test (WP 1. Recover refrigerant (WP 0223 00) and

0018 00) to determine location of leak.

repair leaks.

2. If a large amount of refrigerant was

lost, perform Refrigerant Compressor

Oil Check (WP 0018 00).

3. Evacuate system and re-charge system

with correct amount of refrigerant (WP

0225 00).

4. After system is charged, operate for a

minimum of 10 minutes (TM 5-3805-

291-10) and perform Performance

Checks for AC System (WP 0018 00) to

verify correct operation of AC system.

8. There is air in system.

Reclaim, evacuate, and recharge AC

system (WP 0222 00).

N OT E

Restriction in high pressure liqud line can cause refrigerant to be

i

removed from evaporator at a faster rate. Restriction can cause

evaporator to be low on refrigerant from inline dryer. Clogged filters

or a failure of blower motor can cause possible restrictions to air

flow.

Restrictions of refrigerant flow areidentified by frost or cold spots

in line. Also, restrictions of refrigerant flow are identified by frost or

cold spots in inline dryer.

Cap all open lines andfittings during repairs.

Ambient temperature is above 70F (21C).

0008 00-94