TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

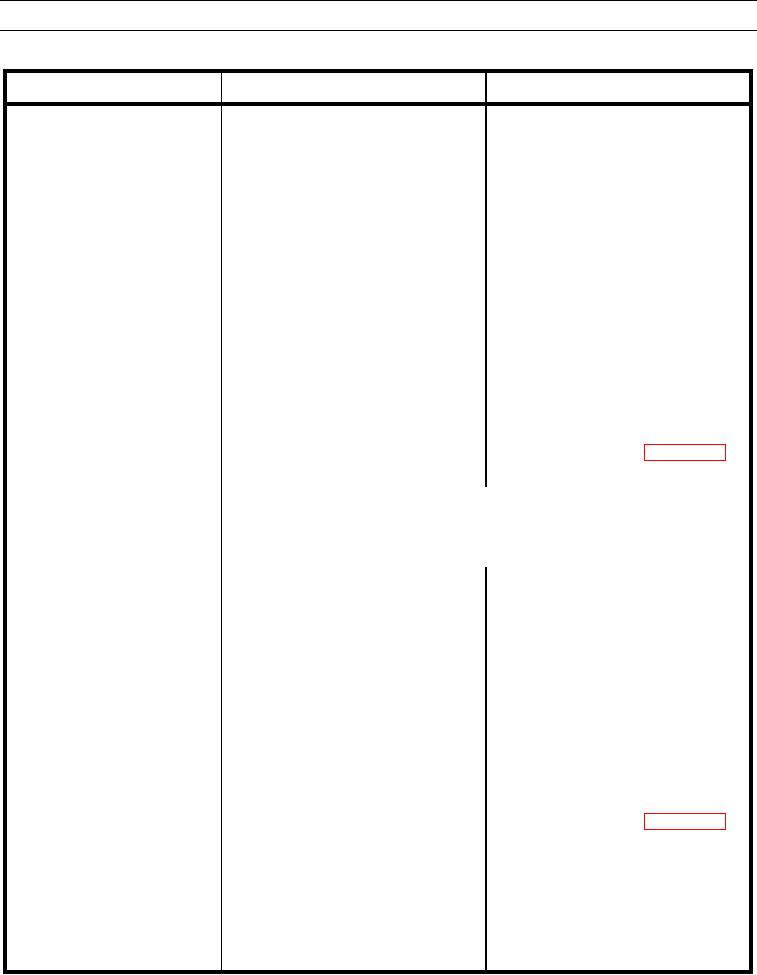

Table 8. AC System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. If low pressure gage reading is normal,

System Only Cools Cab in 1. Check low and high pressure gage

3.

(gage reading may drop into vacuum

during operation of AC.

Morning and in Evening

range during testing procedure) and

Not During Hot Part of Day.

high pressure gage reading is normal

Air Flow is Very Cold but

and is below normal when low pressure

Air Flow Becomes Warm.

gage drops into vacuum range, go to

Test 2.

2. If readings are not as specified, exit this

test.

2. The system has a large amount of

1. Recover refrigerant (WP 0225 00) and

replace inline dryer (WP 0224 00).

moisture. Desiccant in receiver/dryer

Evacuate and charge system with

or inline dryer is full of water. Water is

correct amount of refrigerant. Measure

released during high ambient

refrigerant by weight (WP 0225 00).

temperatures. Ice collects in orifice and

ice can block flow of refrigerant.

2. After system is charged, operate for a

minimum of 10 minutes (TM 5-3805-

291-10) and perform Performance

Checks for AC System (WP 0018 00) to

verify correct operation of AC system.

N OT E

4.

High Pressure (Liquid Line)

is Very Hot. Compressor

The compressor is not operating under ambient temperatures that are

May Become Noisy and

extreme. Compressor is not operating under high humidity that is extreme.

Drive Belt May Slip.

1. Check low and high pressure gage

1. If low pressure gage reading is above

during operation of AC.

normal and high pressure gage reading

is above normal, go to Test 2.

2. If readings are not as specified, exit this

test.

2. The system is overcharged.

1. Recover refrigerant (WP 0225 00) and

replace inline dryer (WP 0224 00).

Evacuate and charge system with

correct amount of refrigerant. Measure

refrigerant by weight (WP 0225 00).

2. After system is charged, operate for a

minimum of 10 minutes (TM 5-3805-

291-10) and perform Performance

Checks for AC System (WP 0018 00) to

verify correct operation of AC system.

Check non-return valve for proper

5.

Water is in Vents and

positioning and direction.

Leaking From Unit.