TM 5-3805-291-23-1

TURBOCHARGER ASSEMBLY, AIR LINES, AND OIL LINES REPLACEMENT - CONTINUED

0032 00

CLEANING AND INSPECTION - CONTINUED

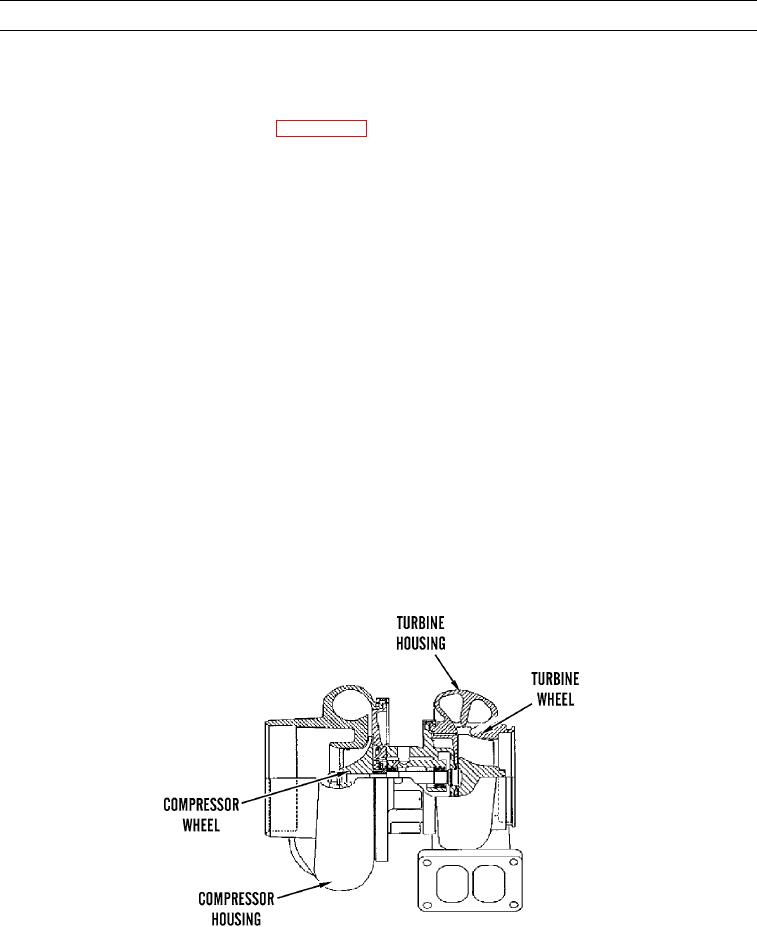

Turbine Wheel and Turbine Housing Inspection

1.

Remove air piping from turbine housing (WP 0040 00).

2.

Inspect turbine for damage by a foreign object. If there is damage, determine source of foreign object. Replace turbo-

charger. If there is no damage, go to step 3.

3.

Inspect turbine wheel for build up of carbon and other foreign material. Inspect turbine housing for buildup of carbon

and foreign material. Clean turbine wheel and clean turbine housing if there is build up of carbon and foreign material.

If there is no build up of carbon or foreign material, go to step 4.

4.

Turn rotating assembly by hand. While you turn assembly, push assembly sideways. Assembly should turn freely. Tur-

bine wheel should not rub against turbine housing. Replace turbocharger if turbine wheel rubs turbine housing. If there

is no rubbing or scraping, go to step 5.

5.

Inspect turbine and turbine housing for oil leakage. Inspect turbine and turbine housing for oil coking. Some oil coking

may be cleaned. Heavy oil coking may require replacement of turbocharger. If oil is coming from turbocharger center

housing, go to step 5a. Otherwise, go to Wastegate Inspection in this work package.

a.

Remove oil drain line for turbocharger. Inspect drain opening. Inspect area between bearings of rotating assembly

shaft. Look for oil sludge. Inspect oil drain hole for oil sludge. Inspect oil drain line for oil sludge. If necessary,

clean rotating assembly shaft. If necessary, clean drain opening. If necessary, clean drain line.

b.

If crankcase pressure is high, or if oil drain is restricted, pressure in center housing may be greater than pressure of

turbine housing. Oil flow may be forced in wrong direction and oil may not drain. Check crankcase pressure and

correct any problems.

c.

If oil drain line is damaged, replace oil drain line.

d.

Check routing of oil drain line. Eliminate any sharp restrictive bends. Makes sure oil drain line is not too close to

engine exhaust manifold.

e.

If steps 5a thru 5d did not reveal source of oil leakage, turbocharger has internal damage. Replace turbocharger.

427-C1976

0032 00-6