TM 5-3805-291-23-2

FLYWHEEL REPLACEMENT - CONTINUED

0177 00

INSPECTION - CONTINUED

Bore Runout (Radial Eccentricity)

0177 00

N OT E

Find top center position for No. 1 Piston.

Always put force on crankshaft in same direction before dial indicator is read. This will remove any

crankshaft end clearance.

1.

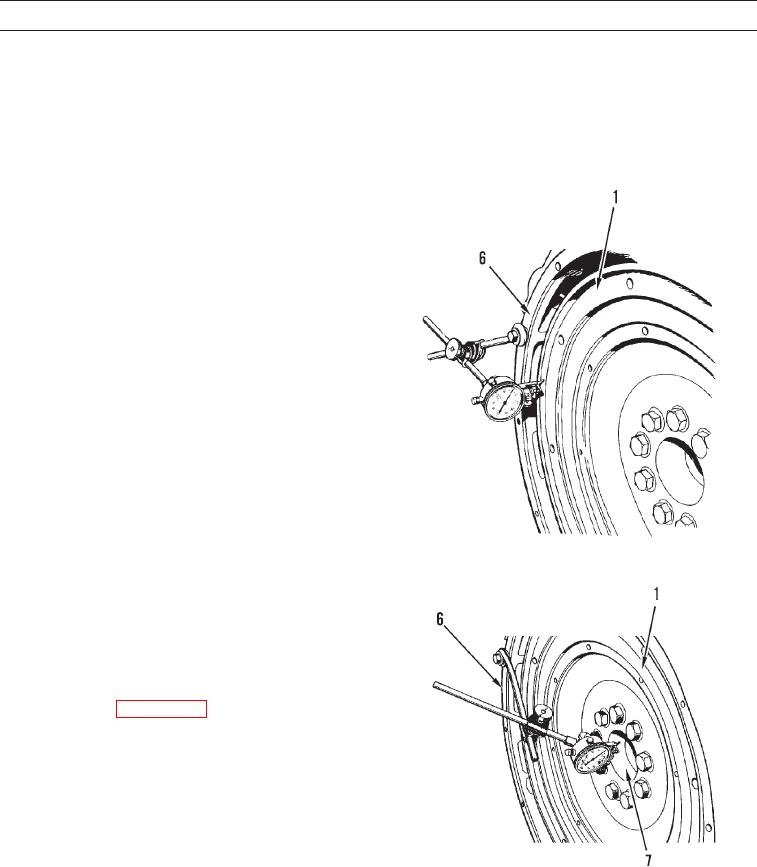

Install dial indicator on bell housing (6) as shown.

2.

Adjust universal attachment so dial indicator makes

contact with flywheel (1).

3.

Set dial indicator to read 0.00 in. (0.0 mm).

4.

Turn flywheel (1) at intervals of 90 degrees and read

dial indicator.

5.

Take measurements at all four points. Difference

between lower measurements and higher measure-

ments at all four points must not be more than 0.006

in. (0.15 mm), which is maximum permissible bore

runout (radial eccentricity) of flywheel (1).

427-C0557

6.

To find runout (eccentricity) of pilot bearing bore (7),

install dial indicator on bell housing (6) as shown and

repeat steps 1 thru 5.

7.

Runout (eccentricity) of pilot bearing bore (7) for pilot

bearing in flywheel (1) must not exceed 0.005 in.

(0.13 mm).

8.

Install engine (WP 0171 00).

427-C0558

9.

Run engine to verify there is no flywheel interference (TM 5-3805-291-10).

10.

Shut down engine and inspect for flywheel interference (TM 5-3805-291-10).

END OF WORK PACKAGE

0177 00-4