TM 5-3805-292-23

0007

ENGINE CONTINUED

Fuel Supply System Check - Continued

0007

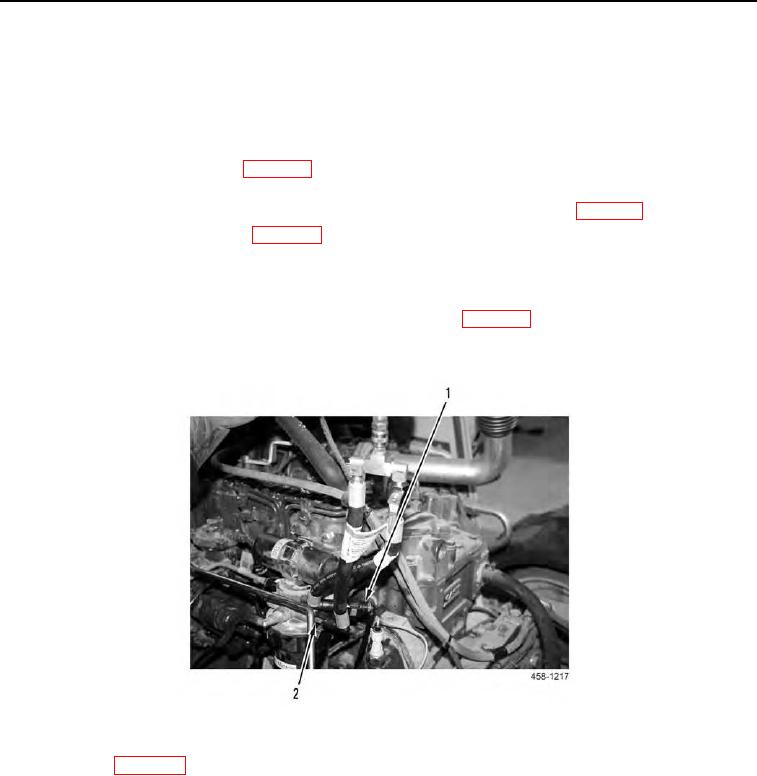

8. Use 3/8 inch quick connect double male to install fuel pressure tester between line (Figure 4, Item 2) and inlet

of fuel lift pump (Figure 4, Item 1). Start engine (TM 5-3805-292-10) and check for the following:

a. Vacuum between inlet of fuel pump and tank exceeding 2 inHg (50.8 mmHg) under full load. If vacuum

reading exceeds 2 inHg (50.8 mmHg):

(1) Replace inline fuel filter (WP 0016).

(2) Check lines and connections from fuel filter inlet back to fuel tank for damaged lines (kinks create

restriction; rub marks may allow air to enter) and leakage at O-ring fittings (WP 0017).

(3) Drain and clean fuel tank (WP 0008).

(4) Check fuel tank cap. Be sure a vacuum is not being formed in fuel tank. A vacuum at tank would

reduce fuel supply pressure to injection fuel pump inlet. Vacuum in fuel tank might not be observable

during short-term running.

b. If vacuum is less than 2 inHg (50.8 mmHg), replace fuel filter (WP 0041).

9. Shut off engine (TM 5-3805-292-10), remove fuel pressure tester, and connect lines.

Figure 4. Fuel Pump Supply.

0007

10. Close ROPS (WP 0134).

END OF TASK