TM 5-3805-292-23

0007

HYDROSTATIC SYSTEM CONTINUED

Checking Anti-Stall Pressure - Continued

0007

9. Disengage park brake (TM 5-3805-292-10).

10. Release door switch.

11. Run engine at high idle (TM 5-3805-292-10).

N OT E

Pressure must be a minimum of 360 psi (24.8 bar) at high idle.

Low idle pressure should be between 150 and 200 psi (10.3 and 13.8 bar).

12. Read pressure gauge and record anti-stall pressure reading at high idle.

13. Slow engine to low idle (TM 5-3805-292-10).

14. Read pressure gauge and record anti-stall pressure reading at low idle.

15. Shut down engine (TM 5-3805-292-10).

16. If pressure is correct, shut off engine, remove gauge, and connect lines. Proceed to step 20.

17. If pressure is not correct, loosen cap on hydraulic reservoir.

N OT E

Turning rod out willincrease pressure.

Turning rod in willdecrease pressure.

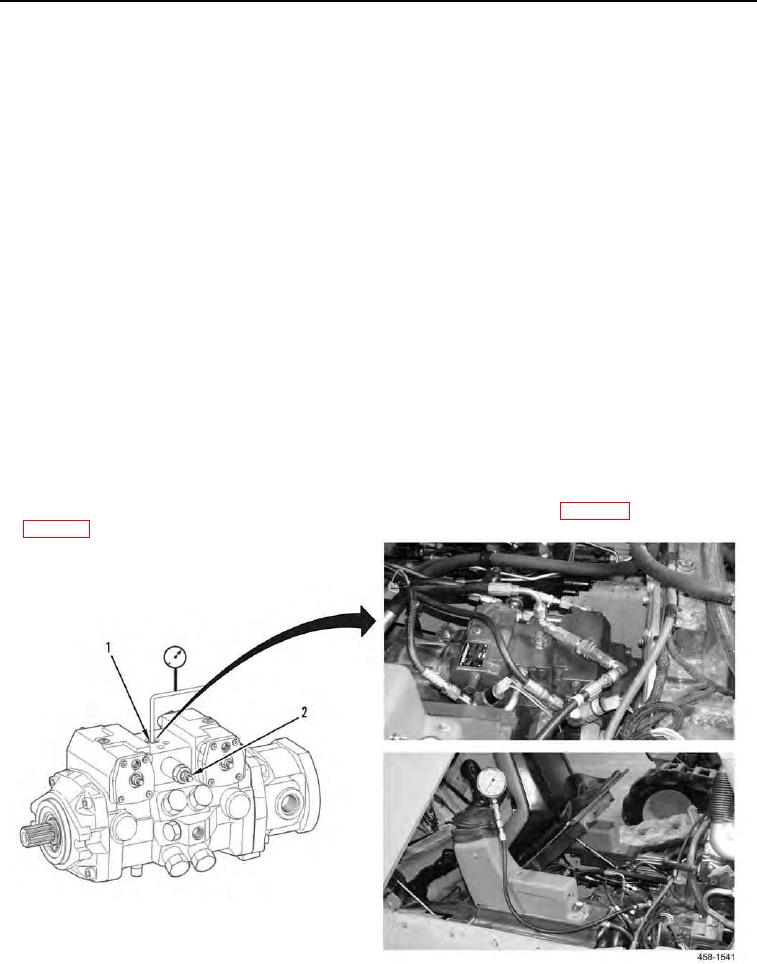

18. Remove cap on end of anti-stall control cartridge (Figure 7, Item 2). Loosen jam nut and turn threaded rod to

adjust.

19. If anti-stall control cartridge (Figure 7, Item 2) is damaged, replace tandem pump (WP 0068 for M400W or

WP 0078 for M400T).

Figure 7. Anti-Stall Control Cartridge.

0007