TM 5-3805-292-23

0086

DISASSEMBLY CONTINUED

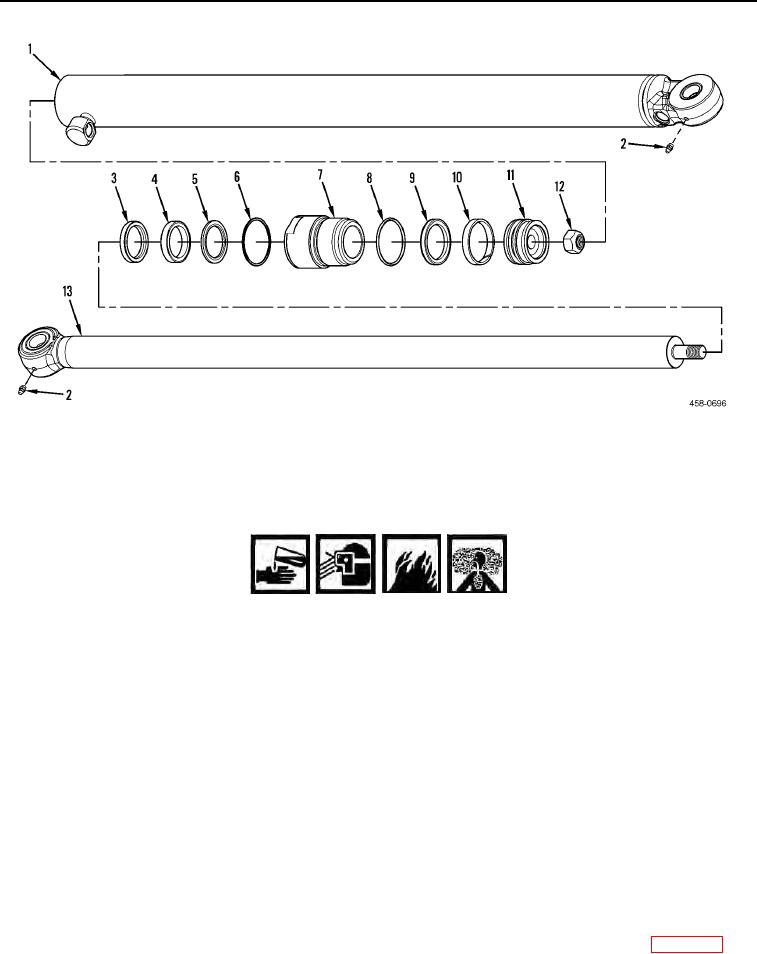

Figure 6. Lift Cylinder.

0086

END OF TASK

CLEANING AND INSPECTION

00086

WARN I N G

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and

low toxic material. However, it may be irritating to the eyes and skin. Use protective gloves

and goggles. Use in well-ventilated areas. Keep away from open flames and other

sources of ignition. Failure follow this warning may result in injury or death to personnel.

1.

Clean piston (Figure 6, Item 11), cylinder head (Figure 6, Item 7), piston rod (Figure 6, Item 13), lift cylinder

(Figure 6, Item 1), and nut (Figure 6, Item 12) in cleaning solvent.

2.

Illuminate inside of lift cylinder (Figure 6, Item 1). Inspect inside of lift cylinder for deep grooves or other dam-

age. Replace parts if damaged.

3.

Inspect piston rod (Figure 6, Item 13) to make sure it is straight. Replace if damaged.

4.

Remove small scratches from inside of lift cylinder (Figure 6, Item 1) with abrasive cloth. Use abrasive cloth

with rotary motion.

5.

Inspect bushings in piston rod (Figure 6, Item 13) end and bushings in lift cylinder (Figure 6, Item 1) end.

Replace bushing(s) if damaged.

6.

Inspect cylinder head (Figure 6, Item 7) for rust or corrosion. Clean and remove rust or corrosion from cylinder

head. Replace if damaged.

7.

Inspect cylinder head (Figure 6, Item 7) and end of lift cylinder (Figure 6, Item 1) for sharp edges that may cut

O-ring (Figure 6, Item 8). Remove sharp edges.

8.

Clean, inspect, and flush hydraulic system IAW Mechanical General Maintenance Instructions (WP 0172).

9.

Remove any marks and sharp edges from chamfer at end of piston rod (Figure 6, Item 13).