TM 5-3805-298-23-2

0174

SPLICING WIRES

000174

NOTE

The use of high-quality splice connectors is essential to ensure optimum electrical

integrity. Use the type and size connector best suited to the application.

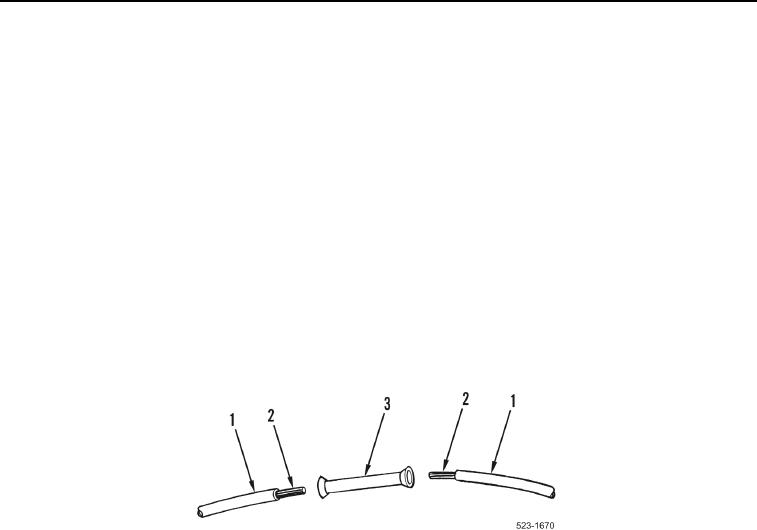

1. Inspect each end of wire (Figure 10, Item 1). Trim insulation and metal strands (Figure 10, Item 2) of

wire back, as necessary, to ensure integrity of wire.

2. Using wire stripping tool, strip each end of wire (Figure 10, Item 1) to expose length of metal strands

(Figure 10, Item 2) suitable for size of splice connector (Figure 10, Item 3).

3. Insert electrical insulating sleeve onto wire. Refer to Heat-Shrinkable Tubing in this work package.

4. Insert metal strands (Figure 10, Item 2) of each wire (Figure 10, Item 1) fully into splice connector

(Figure 10, Item 3).

5. Securely crimp splice connector (Figure 10, Item 3) to metal strands (Figure 10, Item 2) and to insulation of

wire (Figure 10, Item 1).

6. Secure electrical insulating sleeve over the splice. Refer to Heat-Shrinkable Tubing in this work package.

Figure 10. Splicing Wires.

0174

END OF TASK