TM 5-2420-231-23-1

0086

LARGE AND SMALL HYDRAULIC OIL PUMP EFFICIENCY TEST CONTINUED

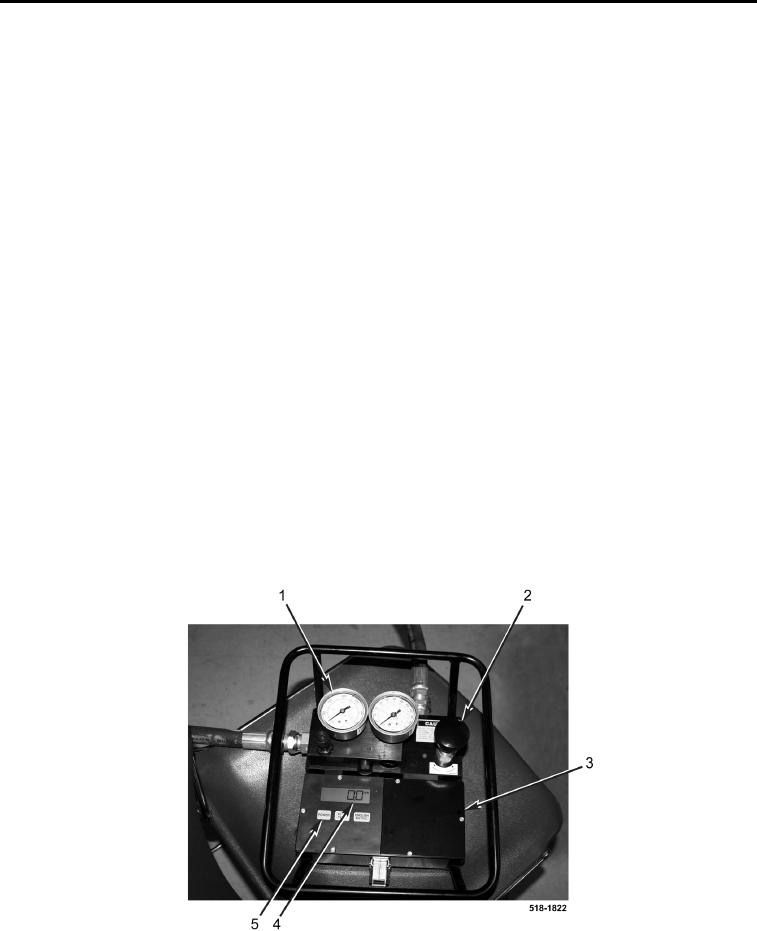

11. Ensure load valve (Figure 31, Item 2) is fully closed by turning clockwise.

12. Run and maintain engine at 2,000 rpm.

13. Press POWER button (Figure 31, Item 5) to activate flow gauge (Figure 31, Item 4).

14. Enable pilot control switch (TM 5-2420-231-10).

15. Curl backhoe bucket in and hold in raised (dead head) position (TM 5-2420-231-10).

NOTE

Ensure jam nut is contacting base of load valve knob.

During adjustment, load valve knob may feel loose.

Ensure engine rpm is maintained for remainder of test.

16. Fully open load valve (Figure 31, Item 2) on flowmeter (Figure 31, Item 3) by turning counterclockwise. Record

flow rate on flowmeter checksheet (5a).

17. Continue to run engine at 2,000 rpm while holding backhoe bucket in deadhead position. Slowly rotate load

valve (Figure 31, Item 2) clockwise until pressure gauge (Figure 31, Item 1) reads 2,000 psi (13,790 kPa).

Read flow gauge (Figure 31, Item 4) and record the reading on flowmeter checksheet (5b).

18. Lower backhoe bucket to ground and turn off machine (TM 5-2420-231-10).

19. On flowmeter checksheet under Pump Efficiency Calculation, divide flow reading (3b) by flow reading (3a).

This answer multiplied by 100 is the percent efficiency of the large pump.

20. On flowmeter checksheet under Pump Efficiency Calculation, subtract flow reading (3b) from flow reading (5b).

This answer is entered under (letter b). Subtract flow reading (3a) from flow reading (5a). This answer is

entered under (letter a). Divide (letter b) by (letter a) and multiply by 100 to get the percent efficiency of both

pumps.

21. If efficiency of either pump is less than 70 percent, replace hydraulic oil pump (WP 0230). If efficiency of both

pumps is at 70 percent or greater, both pumps are good.

Figure 31. Flowmeter.

0086

END OF TASK