TM 5-3805-255-14

0016

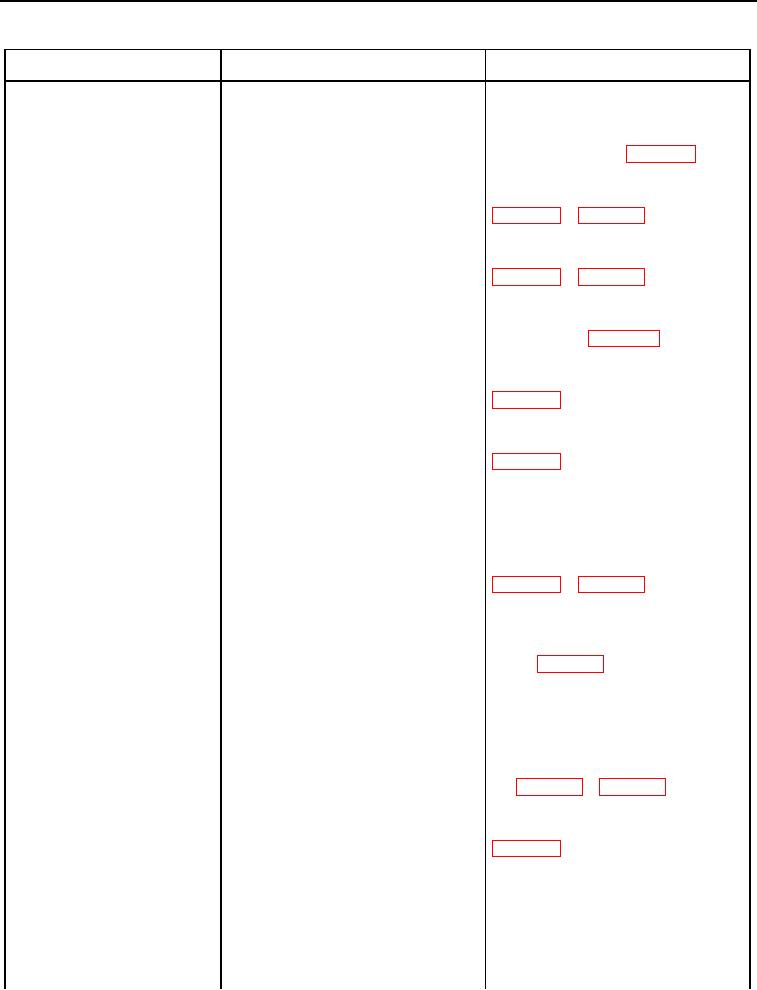

Table 8. Brake System Troubleshooting Procedures for the H100C Loader - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Check for excessive leakage in air

Inspect for leaks and repair or replace

9. Air Pressure Rises to

system.

components as necessary. If problem

Normal Reading Too

still exists, go to step 2.

Slowly.

2. Check for slow engine speed.

Adjust engine speed (WP 0028). If

problem still exists, go to step 3.

3. Check for leaking compressor

Repair or replace compressor

discharge valves.

still exists, go to step 4.

4. Check for defective compressor.

Repair or replace compressor

still exists, notify Sustainment Mainte-

nance.

1. Check for defective air pressure

Replace gauge (WP 0084). If problem

10. Air Pressure Rises

gauge.

still exists, go to step 2.

Above Normal Reading.

2. Check for improper governor

Adjust, repair, or replace governor

adjustment.

(WP 0032). If problem still exists, go

to step 3.

3. Check for defective governor.

Repair or replace governor

(WP 0032). If problem still exists, go

to step 4.

4. Check for restricted line from

Clean, repair, or replace line. If

governor and compressor

problem still exists, go to step 5.

unloading mechanism.

5. Check for defective compressor.

Clean, repair or replace compressor

still exists, notify Sustainment Mainte-

nance.

1. Check for leaking brake treadle

Clean, lubricate, or repair treadle

11. Air Pressure Drops Too

valve.

valves (WP 0061). If problem still

Quickly with Engine

exists, go to step 2.

Stopped and Brakes

Released.

2. Check for leaking hoses or lines.

Repair or replace lines. If problem still

exists, go to step 3.

3. Check for leaking compressor

Clean, lubricate, or repair compres-

discharge valve.

still exists, go to step 4.

4. Check for leaking governor.

Clean, repair, or replace governor

(WP 0032). If problem still exists,

notify Sustainment Maintenance.