TM 5-3805-255-14

0092

CLEANING AND INSPECTION

00092

Piston and Piston Pin

00092

1. Clean and inspect pistons, piston rings, and pins IAW General Maintenance Instructions (WP 0019).

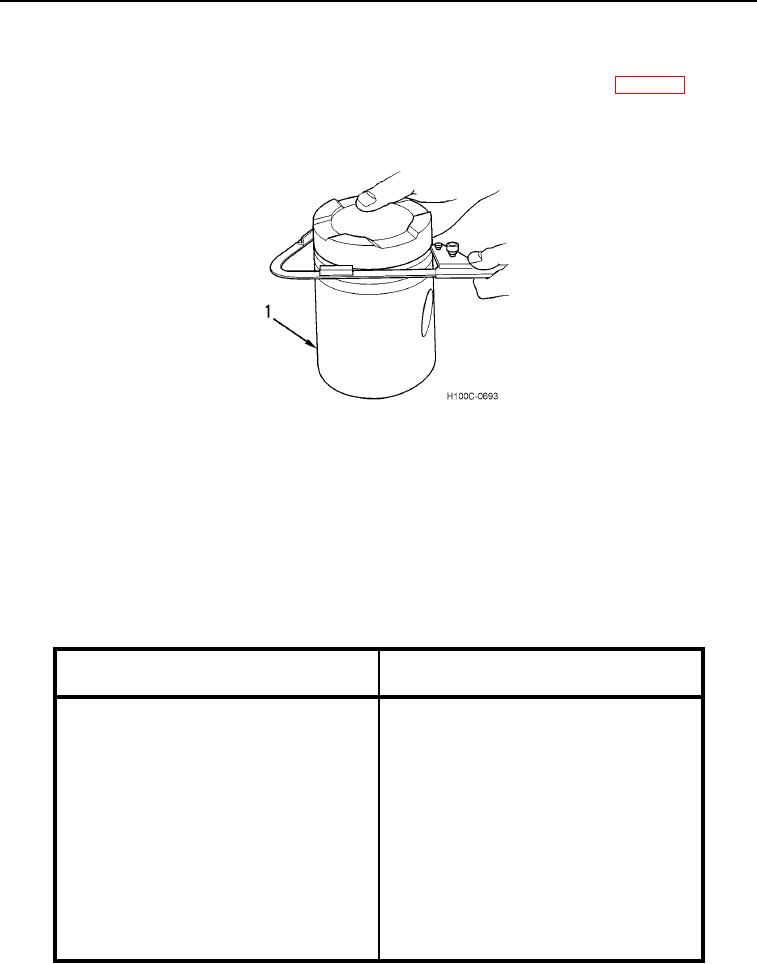

2. Clean all carbon from piston ring grooves using ring groove cleaner or a broken piston ring as shown in Figure

1. Be sure that all oil holes in piston (Figure 1, Item 1) are open.

Figure 1. Cleaning Piston Ring Grooves.

0092

3. Inspect pistons for scuffed or scored skirts and cracked or worn piston ring lands, replace if necessary.

4. Inspect piston pins for wear, replace if necessary.

NOTE

This fit is common on both sides of piston.

5. To check piston pin fit, pins and pistons must be at room temperature 70F (21C). Pin should be a palm-push

fit under these conditions. Refer to Table 1 for clearance specifications.

Table 1. Piston Pin Specifications.

SPECIFICATION

in. (mm)

ITEM

092

092

Pin Diameter

2.2493 to 2.495 in. (57.132 to 57.137 mm)

Pin Length

4.385 to 4.395 in. (111.38 to 111.63 mm)

Clearance (Between End of Pin and Retainer

0.020 to 0.030 in. (0.051 to 0.076 mm)

Ring)

Clearance (Pin to Connecting Rod Bushing)

0.0011 to 0.0015 in. (0.028 to 0.038 mm)

Maximum Permissible Clearance in Rod

0.004 in. (0.10 mm)

(Before Replacing)

Clearance (Pin to Piston)

0.0006 to 0.0010 in. (0.015 to 0.025 mm)

Maximum Permissible Clearance in Piston

0.0025 in. (0.064 mm)

(Before Replacing)

0092-2