TM 5-3805-255-14

0092

CLEANING AND INSPECTION CONTINUED

c.

Subtract outside diameter of piston from inside diameter of sleeve to obtain existing clearance. Refer to

Table 2 for clearance specifications.

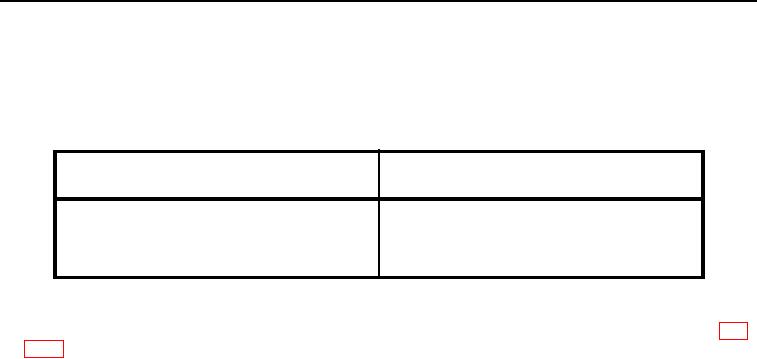

Table 2. Piston Specifications.

SPECIFICATION

ITEM

in. (mm)

092

092

Overall Length

6.778 in. (172.16 mm)

Skirt Clearance (Measured 90 degrees from

0.0061 to 0.0081 in. (0.155 to 0.206 mm)

Oil Hole)

Connecting Rods

00092

1. Clean connecting rod thoroughly and visually inspect for defects IAW General Maintenance Instructions (WP

0019). Be sure collector cup at top of connecting rod is clean and open. Inspect connecting rods for

straightness. Rods must be free of twist and be parallel to pistons.

2. Check fit of piston pin in connecting rod bushing for proper clearance. If greater than maximum allowable

clearance of 0.0061 to 0.0081 in. (0.155 to 0.206 mm), replace bushing (refer to Piston Pin Bushing

Replacement in this work package).

3. Clean connecting rod bolts and nuts.

NOTE

Apply lubricant to bolts and nuts. Hand thread all nuts prior to torquing.

Piston Rings

00092

NOTE

Apply all piston rings when installing pistons.

0092-4