TM 5-3805-255-14

0092

CLEANING AND INSPECTION CONTINUED

NOTE

On a used piston, side clearances tend to increase toward top of piston due to greater

operating temperature prevalent at this point.

4. Check compression rings as follows:

a. Check compression ring grooves using a new keystone ring to correctly establish piston groove wear.

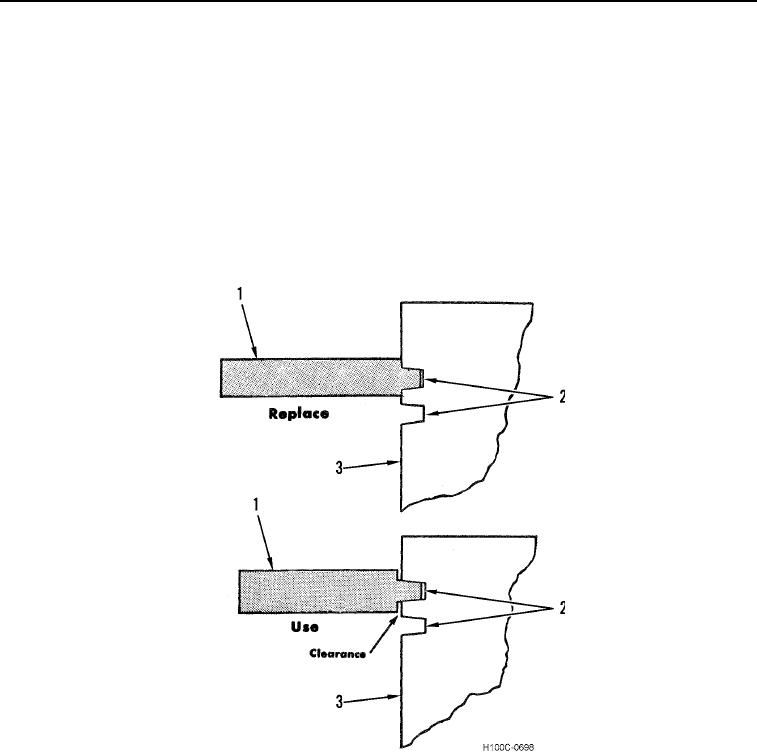

b. Obtain a Perfect Circle piston ring gauge No. 1 (1/8 in. by 15 degrees) (Figure 6, Item 1) and insert it in ring

groove (Figure 6, Item 2). If one or both shoulders on gauge touch ring groove land (Figure 6, Item 2),

piston (Figure 6, Item 3) must be replaced. A groove worn this much would not support ring in operating

position. Install a new piston and rings.

Figure 6. Checking Piston Compression Ring Grooves.

0092

0092-7