TM 5-3805-255-14

0092

CLEANING AND INSPECTION CONTINUED

1. Inspect new rings for any sign of damage before installation.

NOTE

Ensure gap on rings does not extend to end gap.

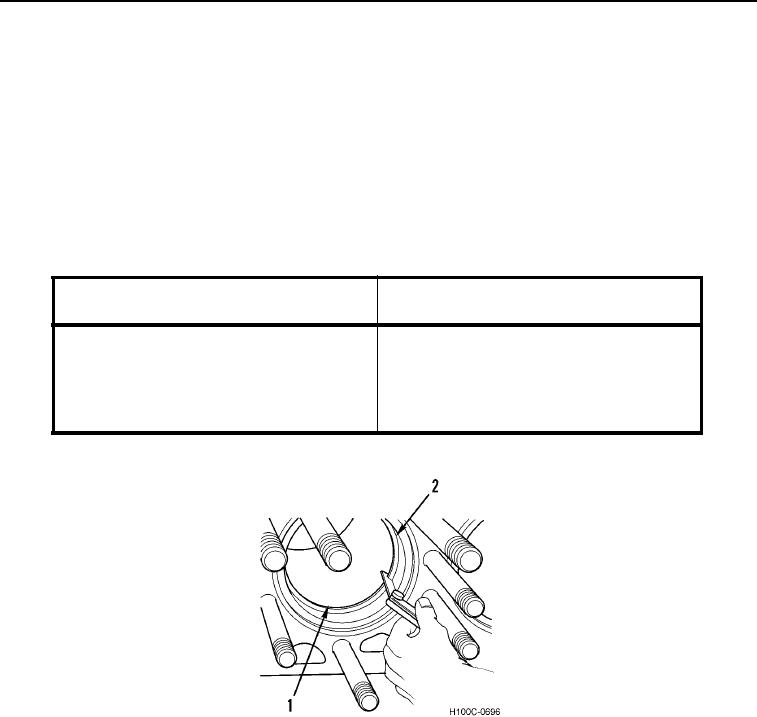

2. Prior to installing rings on pistons, each ring must be checked for proper ring gap. Push ring (Figure 4, Item 1)

down into cylinder sleeve (Figure 4, Item 2) with a piston. This will position ring squarely in sleeve. Extreme

caution must be used during this operation. Check space or gap between ends of ring with a feeler gauge

(Figure 4). Refer to Table 3 for acceptable ring gap specifications. Replace ring if not as specified.

Table 3. Piston Ring Specifications (Compression).

SPECIFICATION

in. (mm)

ITEM

092

092

Ring Gap (Top Ring)

0.020 to 0.030 in. (0.51 to 0.76 mm)

Ring Gap (Intermediate Ring)

0.018 to 0.028 in. (0.46 to 0.71 mm)

Maximum Permissible Ring Gap (Before

0.070 in. (1.78 mm)

Replacing)

Figure 4. Checking Piston Ring Gap.

0092

0092-5