TM 5-3805-255-14

0102

CLEANING AND INSPECTION

000102

Cleaning

000102

Clean all metal parts IAW General Maintenance Instructions (WP 0019) in cleaning solvent and dry with

compressed air. Lubricate all machined surfaces with clean machine oil (WP 0131). During cleaning operation, pay

particular attention to oil passages, bearing assemblies, bearing bores, snap and seal ring grooves, and screw

threads.

Inspection

000102

Inspect all parts for wear or damage. Check converter and rotating housings for cracks. Inspect bearing bores and

mounting faces for wear, grooves, or scratches. Remove burrs and scratches with a crocus cloth. Inspect all

splined parts for worn, twisted, chipped, or burred splines. Remove burrs with a soft stone. Check turbine, impeller,

and guide wheel for cracks or other damage. Replace any parts that are in doubt or cannot be repaired.

END OF TASK

ASSEMBLY

000102

NOTE

Make sure all components are properly seated during assembly.

The ground sleeve hub must be chilled for at least 30 minutes prior to assembly.

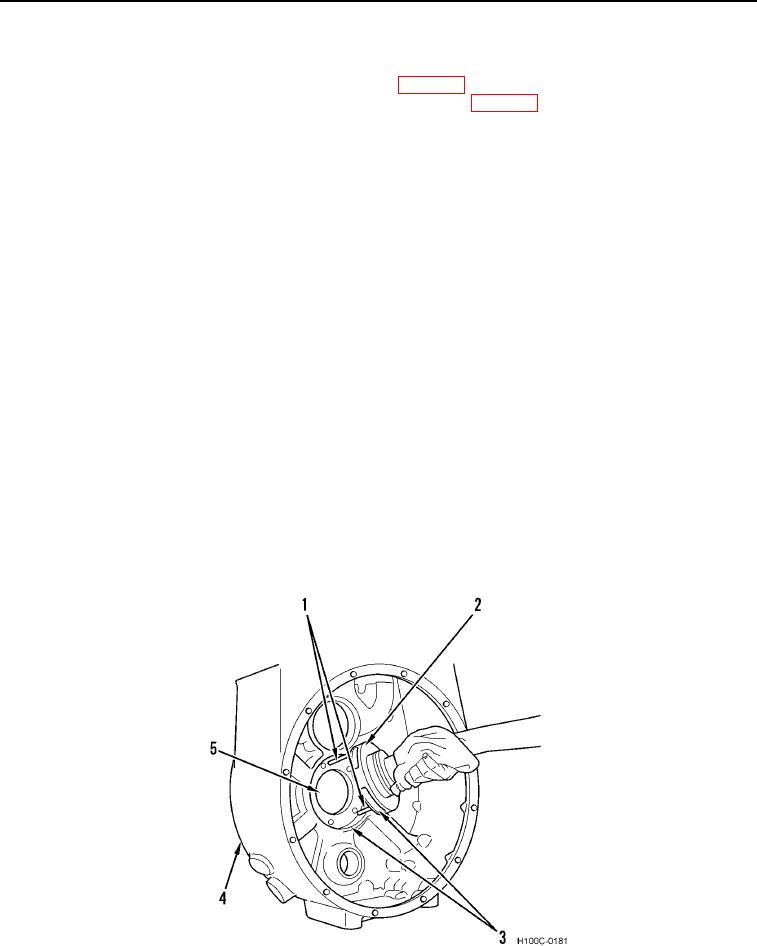

1. Place converter housing (Figure 24, Item 4) in a press with output side down.

2. Position new gasket in housing.

CAUTION

Ensure oil passages (Figure 24, Item 3) are aligned. Failure to follow procedures may

cause damage to equipment.

3. Install ground sleeve hub (Figure 24, Item 2) and position hub in converter housing (Figure 24, Item 4).

Figure 24. Ground Sleeve Hub Installation.

0102

0102-15