Engine Systems

LUBRICATING SYSTEM

bearings. The blower drive gear is lubricated from the

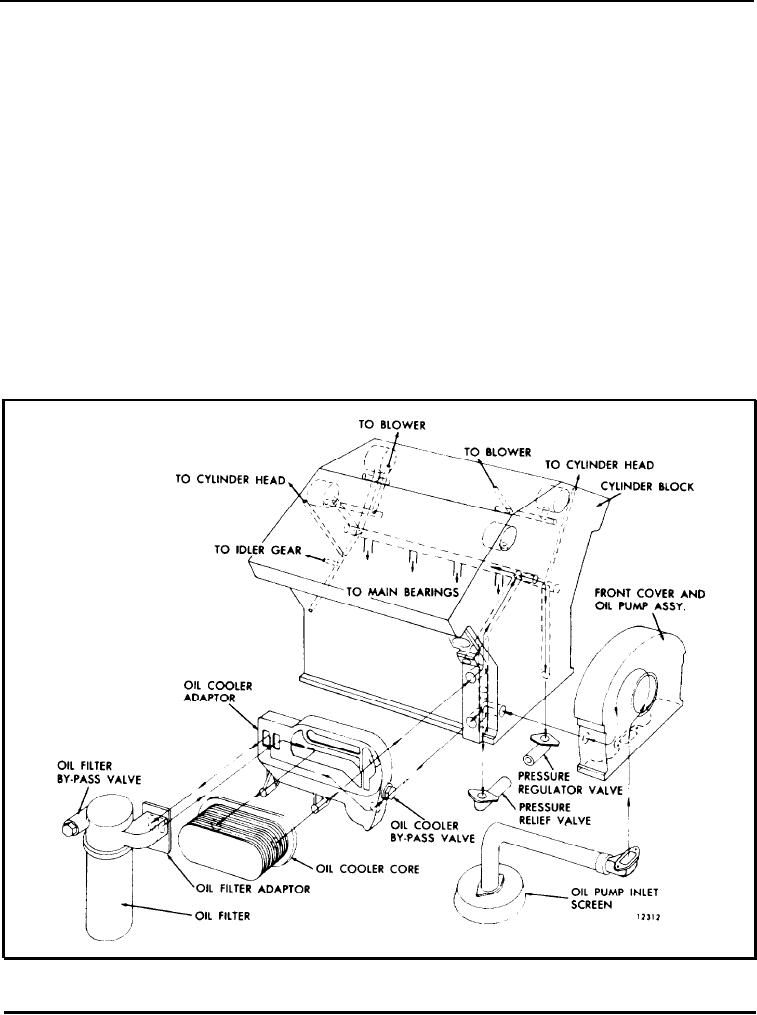

The lubricating oil systems schematically illustrated in

rear of the blower.

Figs. 15, 16 and 17 consist of an oil pump, oil cooler,

a full-flow oil filter, by-pass valves at the oil cooler

The oil pump on the 6 and 8V engines is driven by a

and filter and pressure regulator valves at the pump

pump drive hub on the front end of the crankshaft

and in the cylinder block main oil gallery. Positive

and consists of a large and small spur gear meshing in

lubrication is ensured at all times by this system. A

a cavity inside the crankshaft cover.

by-pass oil filter may also be incorporated into the

lubricating system at the owner's option.

The gear-type oil pump used on the 12 and 16V

engines is mounted on the main bearing caps. The

pump on the 12V engine is driven from the front end

Oil for lubricating the connecting rod bearings and

of the crankshaft and on the 16V engine the pump,

piston pins and for cooling the piston head is provided

which is mounted on the No. 9 and 10 main bearing

through the drilled hole in the crankshaft from the

caps, is driven from the rear end of the crankshaft.

adjacent forward main bearings. The gear train is

lubricated by the overflow of oil from the camshaft

The pressure regulator valve, located at the end of a

pocket through a connecting passage into the flywheel

vertical oil gallery in the front of the cylinder block,

housing. A certain amount of oil spills into the

maintains a stabilized oil pressure. The l6V engine

flywheel housing from the camshaft and idler gear

has two pressure regulator valves located at the ends of

Fig. 15 - Schematic Diagram of Typical 6V and 8V Lubricating Systems

Page 22