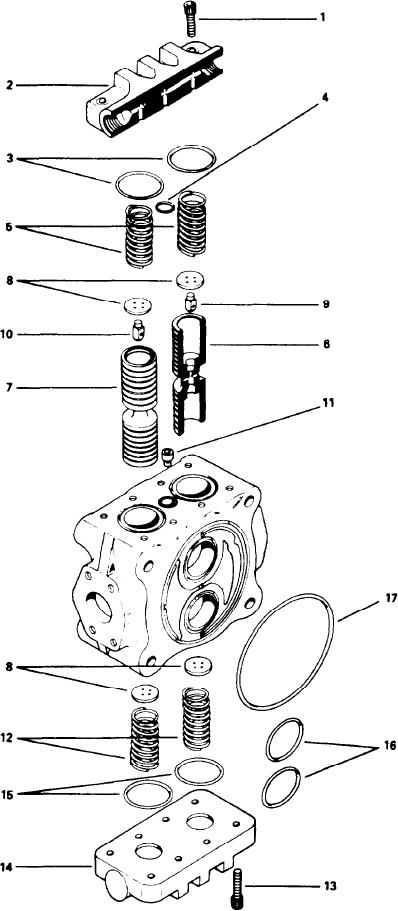

DISASSEMBLY

BUCKET PLUNGER SECTION

Note the position of parts during disassembly so

they can be reassembled in the correct position.

Mark both covers (2 & 14) to insure correct reas-

sembly. Remove the eight socket screws (1). cover

(2). O-rings (3 & 4). springs (5). and washers (8).

(8).

IMPORTANT: Mark each spool (6 & 7) with re-

spect to their proper bore and position (top and

bottom) before removing spools from plunger sec-

tion. Reversing spools will result in the malfunction

of this section.

The spools are a select fit and it may be necessary

to turn section on an angle to facilitate removal.

Identification of each poppet (9 & 10) with respect

to its spool is mandatory. Remove spools (6 & 7),

p o p p e t s (9 & 10) and check valve (11). Remove

eight socket screws (13), blank cover (14), springs

(12) and O-rings (15).

INSPECTION

Clean all parts (including subassemblies in sol-

vent and dry with compressed air. Examine all O-

rings for damage or deterioration. Examine springs

for breaks or distortion. Inspect both the poppet

f a c e s and corresponding seating surfaces in the

spools. All seats must be sharp and free of nicks.

Examine spools and bores for scratches or scoring.

Test spools for fit in their respective bore. Spools

should fit snugly without binding through a com-

plete revolution. Follow same procedure for fit be-

t w e e n the check valve and housing. Inspect the

flow passages in spools and spool covers. These

passages must be clean and free from foreign par-

t i c l e s . Clean passages with compressed air. Re-

place defective parts.

ASSEMBLY

Coat all parts, including housing bores, with hy-

draulic oil. Insert poppets (9 & 10) into spools (6

& 7). POPPETS MUST BE INSTALLED IN CORRECT

POSITION.

Install washers (8) and springs (5 & 12) into spools

(6 & 7). Slide spools into their respective bores. IT

IS VERY IMPORTANT THAT SPOOLS ARE POSI-

TIONED CORRECTLY.

Place O-rings (3, 4 & 15) into their corresponding

grooves. A light coating of grease will hold them

in place. Install check valve poppet (11). Attach

cover (2) with socket screws (1) and tighten to 60

ft. lb. (8,3 kg. mtrs.). Attach cover (14) with socket

screw (13) and hand tighten.

[30]