TM 5-3805-258-24-1

A I R S Y S T E M A N D B R A K E S

S Y S T E M S O P E R A T I O N

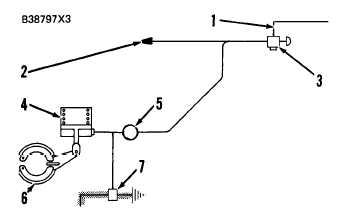

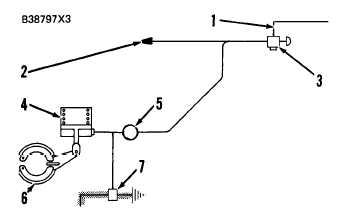

AIR CIRCUIT FOR THE EMERGENCY AND PARKING BRAKE

engaged. The transmission control lever must be held

in position, with a much higher force than normal, to

A I R C I R C U I T F O R T H E E M E R G E N CY

A N D P A R K I N G B R A KE

1. Line from left brake control valve. 2. Line to transmis-

s i o n n e u t r a l i z e r g r o u p . 3 . C o n t r o l v a l v e f o r e m e r g e n c y

and parking brake. 4. Brake chamber for emergency and

parking brake. 5. Quick release valve. 6. Emergency and

parking brake. 7. Air pressure switch.

The components of the air circuit for the emer-

gency and parking brake are a control valve, an

air pressure switch, a quick release valve, a brake

chamber and a brake.

Air pressure (from the left brake control valve)

goes to control valve (2), which controls the opera-

tion of brake chamber (6). When air pressure is

sent to the brake chamber, emergency and parking

brake (7) is disengaged (released). When air pres-

sure to the brake chamber is released, a spring in

the brake chamber engages (activates) the emer-

gency and parking brake.

Quick release valve (8) decreases the time it takes

to engage emergency and parking brake (7). The

air is released at the quick release valve instead of

at control valve (2).

Switch (4) activates the warning system in the

operator’s station when the parking brake control

knob is in the ON position.

The emergency and parking brake is used to stop

the machine in an emergency when the machine is in

operation. It is also used as a parking brake when the

machine is not in operation. Brake (7) is activated

automatically when the air pressure goes below 275

kPa (40 psi). When the parking brake is activated,

the transmission is automatically shifted into neutral.

The transmission neutralizer group prevents dam-

age to the parking brake when the parking brake is

activated. The machine can be moved, in an emer-

gency, a very short distance with the parking brake

3-74

move the machine in this condition.

CAUTION

The machine can only be moved a very short

distance with the parking brake engaged or the

brake will be destroyed.

CONTROL VALVE FOR THE EMERGENCY

AND PARKING BRAKE

Control valve (1) for the emergency and parking

brake is fastened to the lower end of the steering

column. The valve is activated either manually or

automatically. The valve is controlled manually by a

cable assembly that is connected to knob (2) on the

upper end of the steering column. The valve is acti-

vated automatically when pressure in the air system

is too low.

L O C A T I O N O F T H E C O N T R O L V A L VE

1. Control valve.

When the machine is started, the air reservoir will

be discharged. The control valve will be in the ON

position (pulled out). Valve (9) will be against valve

body (4). The air can not go through outlet port (7)

or exhaust port (11). The air pressure in the reservoir

will go up to the correct pressure for operation.