TM 5-3805-258-24-1

A I R S Y S T E M A N D B R A K E S

S Y S T E M S

O P E R A T I ON

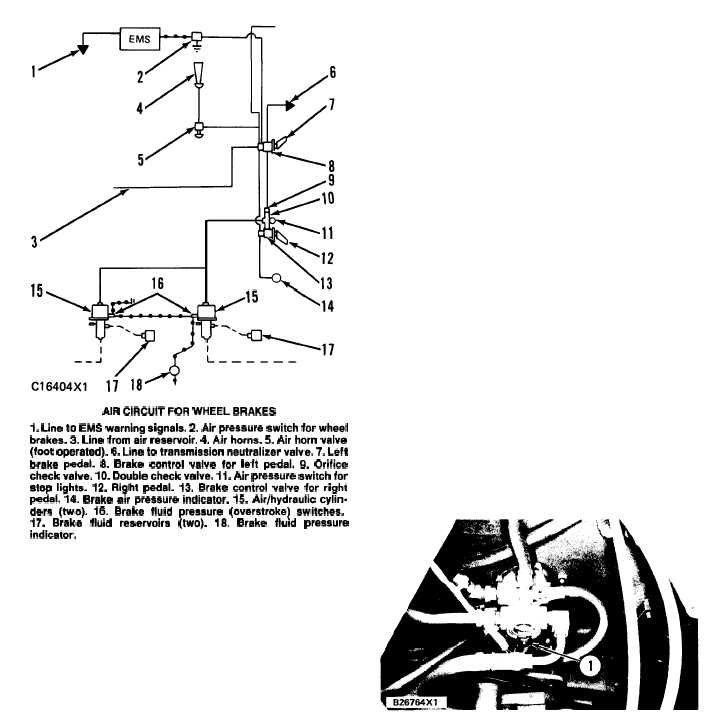

AIR CIRCUIT FOR THE WHEEL BRAKES

AIR CIRCUIT FOR WHEEL BRAKES

1. Line to EMS warning signals. 2. Air pressure switch for wheel

brakes. 3. Line from air reservoir. 4. Air horns. 5. Atr horn valve

(foot operated). 6. Line to transmission neutralizer valve. 7, Left

brake pedal. 8. Brake control valve for left pedal. 9. Orifice

check valve. 10. Double check valve. 11. Air pressure switch for

stop lights. 12. Right pedal. 13. Brake control valve for right

pedal. 14. Brake air pressure indicator. 15. Air/hydraulic cylin-

ders (two). 16. Brake fluid pressure (overstroke) switches.

17.

Brake fluid reservoirs (two). 18. Brake fluid pressure

indicator.

The air circuit for the wheel brakes sends air under

pressure from the air reservoir to operate the air/hy-

draulic cylinders and the air horns.

Switch (2) activates the warning system in the

operator’s station when air pressure in the system

is too low.

Horn valve (5) activates air horn (4).

When left brake control valve (8) is activated, the

wheel brakes engage and the transmission neutralizer

valve is activated. The transmission neutralizer valve

stops oil pressure to the directional clutch circuit,

which disengages the directional clutch. Since a speed

and direction clutch must both be engaged before pow-

er goes through the transmission, power does not go

through the transmission when the left brake pedal is

pushed. The surface area of the neutralizer valve is

smaller than the surface area of the air cylinder piston.

This difference in area causes the transmission to dis-

engage before the wheel brakes are engaged.

When control valve (8) is released, orifice check

valve (9) causes a restriction to the flow of air from

the air cylinders to brake control valve (8). This

permits the transmission to engage before the

brakes are released.

Air pressure from the orifice check valve goes to

double check valve (10). Valve (10) lets air go to

the air cylinders and will not let air go to control

valve (13). When control valve (13) is activated,

valve (10) lets air go to the air cylinders and will

not let air go to valve (9).

Right brake control valve (13) activates the

wheel brakes only. When either control valve (8)

or (13) is activated, stop light switch (11) activates

the stop lights at the rear of the machine.

Air/hydraulic cylinders (15) have two cylinders

each, one for air (air cylinder) and one for brake

fluid (master cylinder). Movement of the air cyl-

inder is caused by air pressure. This movement also

causes the master cylinder to move and the wheel

brakes are activated. The master cylinder is part

of the hydraulic circuit for the wheel brakes.

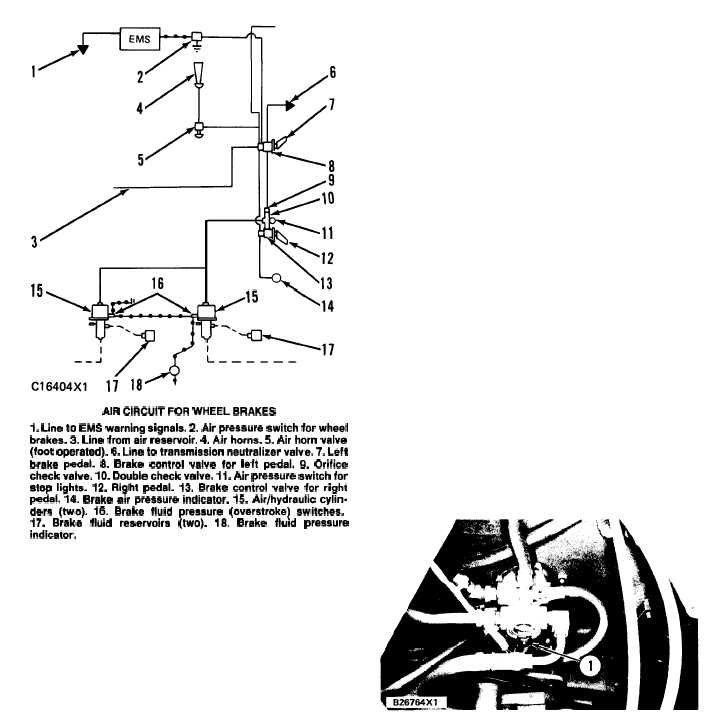

AIR PRESSURE SWITCH FOR

WHEEL BRAKES

L O C A T I O N O F T H E A I R P R E S S U R E S W I T CH

1. Switch.

Air pressure switch (1) is activated when the air

pressure in the brake system gets below approximately

450 kPa (65 psi). The switch causes the brake air pres-

sure indicator and the master fault light in the dash to

come ON, and also the fault alarm will sound.

Switch (1) is under the floor of the operator’s station.

It is fastened to the left brake control valve.

3-79