TM 5-3805-258-24-1

H Y D R A U L I C S Y S T E M

S Y S T E M S O P E R A T I O N

HYDRAULIC SYSTEM

INTRODUCTION

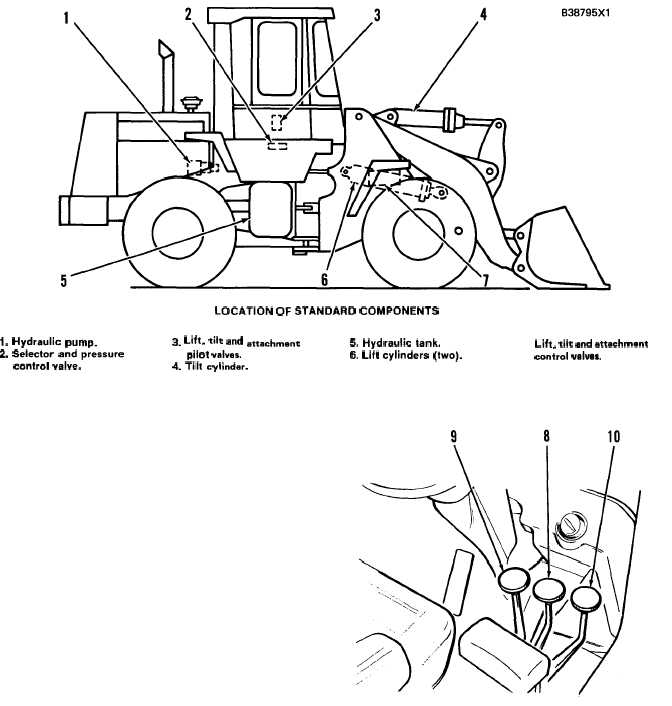

LOCATION OF STANDARD COMPONENTS

1. Hydraulic pump.

3. Lift, tik and attachment

5. Hydraulic tank.

2. Selector andpresaure

pilot valves.

6. Lift cylinders (two).

control valve.

4. Tilt cylinder.

The implement hydraulic system controls the

operation of the bucket and attachment (log fork,

side dump or multi-purpose bucket, etc.). There

are two separate oil systems in the implement

hydraulic system: pilot oil system and main

(implement) oil system. The implement oil system

is controlled by the pilot oil system. The standard

implement hydraulic system has a hydraulic pump

(1), hydraulic tank (5) with oil filters, selector and

pressure control valve (2), lift and tilt pilot valve

(3), lift and tilt (two spool) control valve (7), con-

trol linkage with electrical bucket positioner and

lift kickout, tilt cylinder (4) and lift cylinders (6).

The implement hydraulic system, in addition

to these components, has an attachment (third)

pilot valve, attachment (three spool control valve,

sequence valve,

shuttle valve and attachment

cylinders. To control the attachment, an additional

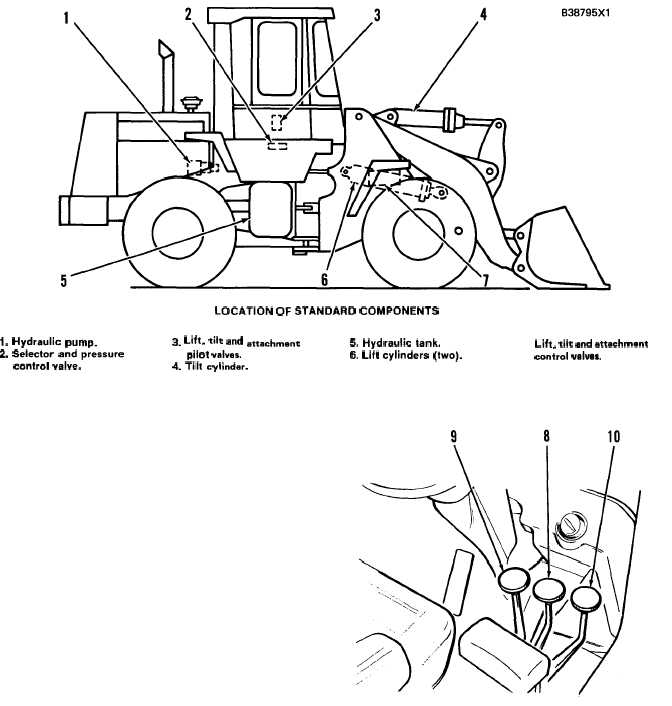

control lever (10) is added in the operator’s station.

This third lever is to the right of lift control lever

Lift, tilt and attachment

control valvea.

(8).

The hydraulic system is an open center, pilot

operated circuit. The flow of oil through the sys-

tem is not completely continuous. Hydraulic pump

CONTROL LEVERS

(1) for the hydraulic system is a three section

8. Lift control lever.

9. TiIt control lever.

10. Attachment

pump (implement, steering and pilot).

control lever.

3-89