TM 5-3805-258-24-1

H Y D R A U L I C

S Y S T E M

S Y S T E M S O P E R A T I O N

In operation with the lift hydraulic circuit is the

bucket lift kickout. It consists of lift detent lever

(13), a roller and linkage, lift kickout solenoid (14),

a magnet and lift kickout switch (21). The lift kick-

out moves lift control lever (8) from the raise detent

[on lever (13)] in RAISE position to the HOLD

position. This happens as the bucket lift arms

move from lower to raise when they get to correct

bucket lift height. There is also a FLOAT detent

on lift detent lever (13). The lever must be manually

moved out of the FLOAT detent position, there

is no kickout.

L E F T S I D E O F L O A D E R F R A ME

21. Lift kickout switch.

HYDRAULIC PUMP

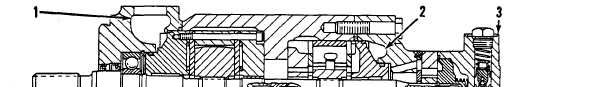

HYDRAULIC PUMP WITH THREE SECTIONS

1. Implement pressure outlet. 2. Steering pressure outlet. 3. Housing for pilot section

relief valve. 4. Implement section. 5. Inlet from tank. 6. Steering section. 7. Pilot section.

The hydraulic pump is a three section vane-type

pump. Steering section (6) and implement section

(4) are the cartridge type. The steering section pro-

vides the oil needed to operate the steering cylinders.

The implement section provides the oil needed to

operate the bucket and any attachments in the imple-

ment hydraulic system. Pilot section (7) is a straight

vane-type pump (it has no vane inserts). The pilot

section provides the oil needed to operate the hand

metering unit of the steering hydraulic system. It

also provides the oil needed to operate the pilot valves

of the implement hydraulic system.

All three pump sections get oil from the hydraulic

tank through inlet (5). Each section has its own

outlet. Pilot section (7) has a relief valve in housing

(4). The extra oil from the relief valve goes through

pilot drain outlet (2) and back to the tank.

Operation Of The Steering And Implement

Pump Sections

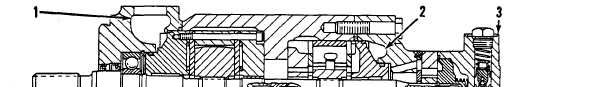

The components of both the steering and imple-

ment cartridges are similar: inlet and outlet support

plates, seal packs, flex plates, cam ring (1), rotor (2),

vanes (4) and inserts (9).

Since both pump sections (cartridges) are similar

only the description of one cartridge is given. Grooves

in the flex plates send pressure oil to slots (6) in rotor

(2). Oil from these slots goes into the area between

inserts (9) and vanes (4). This pushes the vanes out

against cam ring (1).

3-92