HYDRAULIC SYSTEM

TM 5-3805-258-24-1

SYSTEMS OPERATION

is held in passage (19)]. Lift stem (13) is now pushed

off of retainer (6) and is held (floating) in a pressure

modulating position. The lift stem keeps a balance

between the pressure in passage (19) and the force of

spring (7).

When the lift control lever is released, spring (9)

pushes up on plunger (4). Actuator (1) turns shaft

(2) and the lever moves back to HOLD position. Lift

stem (13) moves up because retainer (6) has moved

up (with the plunger) and the force of spring (7) is

less. The oil in passage (19) can now go through holes

(15) and tank passage (11). The centering springs on

the lift valve spool in the lift and tilt control valve

move the valve spool back to HOLD position. The

extra oil from the end of the lift valve spool also goes

through holes (15) and tank passage (11).

NOTE: The farther the lift control lever is moved

into RAISE position, the more plunger (4) and lift

stem (13) move. Thus there is more compression on

spring (7) and the pressure in passage (19) increases.

The lift valve spool now moves farther and lets more

oil go to the head end of the lift cylinders. So the

bucket lifts faster.

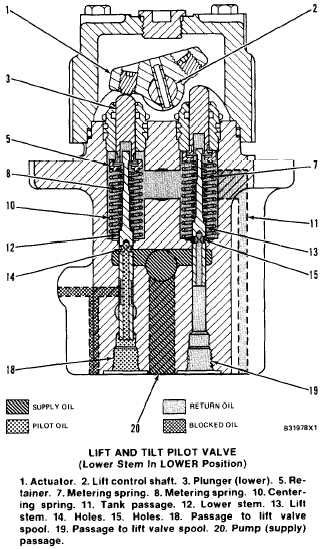

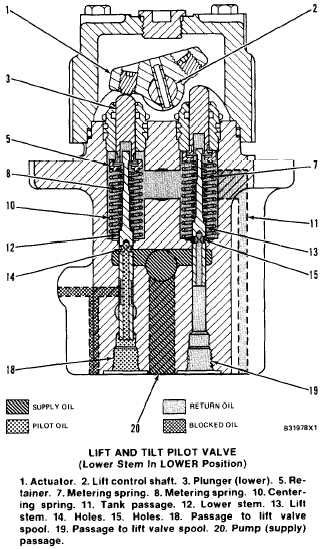

LOWER Position

Lower stem (12) has two purposes: to send pres-

sure oil to the lift valve spool and provide exact

movement of the valve spool during LOWER opera-

tions; to release pressure (vent) in the spring passage

of the make-up valve for the rod end of the lift

cylinders during FLOAT operations.

When the lift control lever is moved into LOWER

position, shaft (2) and actuator (1) turn in the direc-

tion shown. The actuator pushes plunger (3) down

against the force of spring (8). Lower stem (12)

moles down with the plunger. The oil from pump

passage (20) now goes through holes (14) and out

passage (18) to one end of the lift valve spool. The

pressure of this oil, controlled by the force of spring

(8). moves the lift valve spool into LOWER position.

The oil from the chamber at the opposite end of the

lift valve spool comes back through passage ( 19).

This oil goes through holes (15) of lift stem (13) into

tank passage (11).

Oil pressure in passage (18) pushes up against

lower stem (12) and spring (8). A small pressure

increase in passage (18) pushes lower stem (12) up

against the force of spring (8). The flow of pressure

oil through holes ( 14) and passage ( 18) is stopped

[the pressure is held in passage (18)]. Lower stem

(12) is now pushed off of retainer (5) and is held

(floating) in a pressure modulating position. The

lower stem keeps a balance between the pressure in

passage ( 18) and the force of spring (8).

3-97

As the lift control lever [and actuator (1) and

plunger (3)] is moved farther into LOWER position,

plunger (3) comes in contact with lower stem (12).

Holes (14) now become fully open to oil from pump

passage (20). This now moves the lift valve spool

completely to LOWER or full “power down” posi-

tion. The maximum amount of oil now goes to the rod

end of the lift cylinders. So the bucket lowers faster.

When the lift control lever is released, spring (10)

pushes up on plunger (3). Actuator (1) turns shaft

(2) and the lever moves back to HOLD position,

Lower stem (12) moves up because retainer (5) has

moved up (with the plunger) and the force of spring

(8) is less. The oil in passage (18) can now go through

holes (14) and tank passage (11). The centering

springs on the lift valve spool in the lift and tilt

control valve move the valve spool back to HOLD

position. The extra oil from the end of the lift valve

spool also goes through holes (14) and tank passage

(11).