H Y D R A U L I C

S Y S T E M

TM 5-3805-258-24-1

S Y S T E M S

O P E R A T I O N

When the engine is off and the lift arms are raised,

check valve (4) will permit pressure oil from the head

end of the lift cylinders to go to the selector and

pressure control valve for operation of pilot valves.

Check valve (2) will not let the oil from the head end

of the lift cylinders go into the pilot pump section.

Pressure oil at inlet passage (6) pushes valve (7)

against spring (8). The oil is then free to go through

holes (9) in valve (7) and out outlet passage (10).

Pressure oil at outlet passage (10) pushes against

valve (7) and holds it closed. No oil can flow through

the check valve.

SELECTOR AND PRESSURE CONTROL VALVE

The selector and pressure control valve is in the

pilot oil system. It sends oil to the lift and tilt pilot

valve for its operation. The selector and pressure

control valve makes pressure oil available to the pilot

valve to lower a raised bucket (lift arms) when the

engine is off.

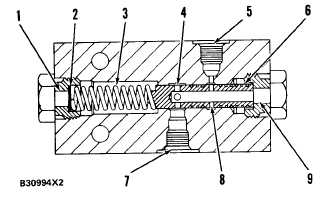

S E L E C T O R A N D P R E S S U R E C O N T R O L V A L V E

1. Drain passage. 2. Spacers. 3. Spring. 4. Holes (four). 5.

I n l e t p a s s a g e f r o m h e a d e n d o f l i f t c y l i n d e r s . 6 . V a l ve

spool. 7. Inlet passage from pilot pump section. 8. Holes

(two). 9. Outlet passage to lift and tilt pilot valve.

During normal operation, pressure oil from the pilot pump

section goes through inlet passage (7). The pressure of this

oil is controlled by the pilot relief valve. This oil goes

through holes (4) in valve spool (6), through the center of

the valve spool and out outlet passage (9) to the lift and

tilt pilot valve. This oil can not go through holes (8) and

out inlet passage (5). There is a check valve in this line to

stop the flow of oil to the head end of the lift cylinders.

When the engine is off, there is no pressure oil at inlet

passage (7). When the engine is off and the lift arms are

raised, the pressure from the head end of the lift cylinders

is in inlet passage (5). This oil is stopped (held) in the

lines as long as the lower stem in the lift and tilt pilot

valve is in the HOLD position. When the lower stem is

moved to LOWER position, the pressure oil from the head

end of the lift cylinders can now go through holes (8) in

valve spool (6), through outlet passage (9), the pilot valve,

and on to the lift valve spool in the lift and tilt control

valve. The lift valve spool moves to LOWER position and

the lift the lift arms will lower. A check valve in the line

from inlet passage (7) will not let oil go to the pilot pump

section.

NOTE: When the engine is off and the lift arms are

raised, the bucket can also be dumped.

When the engine is off, valve spool (6) also con-

trols the pressure of the oil from inlet passage (5) to

the pilot valve [approximately 1030 kPa (150 psi)].

When the pressure through outlet passage (9) gets

too high, the pressure will cause valve spool (6) to

move against the force of spring (3). This decreases

the flow of oil through holes (8) in the valve spool and

decreases the pressure in outlet passage (9).

LIFT AND TILT PILOT VALVE

The lift and tilt pilot valve is controlled manually

by the operator. It sends oil from the pilot system to

the lift and tilt control valve which controls the oper-

ation of the lift and tilt cylinders. There are four

valve stems (of the pressure metering type) in the lift

and tilt pilot valve. Two valve stems are needed for

each operation of lift and tilt.

When a lift or tilt control lever is moved, one

plunger is pushed down in the pilot valve. The

plunger causes a valve stem to move down and send

pilot oil to one end of a valve spool in the lift and tilt

control valve. The valve spool then moves and pushes

oil, from the opposite end of the valve spool, out of the

lift and tilt control valve. The oil goes back to the

pilot valve to another valve stem. The oil then goes to

drain through tank passage (11).

Three of the valve stems in the pilot valve are the

same: dump stem, tilt back stem and lift stem (13).

Lower stem (12) is longer than the other three stems.

All four stems are held in place the same way.

HOLD Position Of Lift Operation

When the lift control lever is in HOLD position,

plungers (3) and (4) are in the same position (as

shown). The plungers do not push up against actua-

tor (1) in the hold position. Pressure oil from the pilot

pump section goes through pump passage (20) and is

stopped by the position of stems (12) and (13). Holes

(14) and (15) are open to tank passage (11).

3-95